Weekly Robotics News covers humanoid robots, factory automation, medical and nuclear robotics, AI “universal brains” and global trends in automation.

Table of Contents

1) Boundless Power Raises ¥300M for a “Robot Universal Brain”

Boundless Power’s universal robot brain backs China’s next AI wave | Weekly Robotics News | The Bolt and the Byte

Story

In other automation news this week, former Horizon Robotics VP Zhang Yufeng has secured about 300 million RMB in angel funding for his new startup Boundless Power, which wants to build a “robot universal brain” — an AI platform that can coordinate many different kinds of robots through one shared intelligence stack. Pandaily

The idea is to make robot intelligence more like cloud computing: instead of every manufacturer reinventing navigation, manipulation, and perception, Boundless Power provides a generalized “brain” that can be plugged into humanoids, mobile platforms, and industrial arms. Early investors are betting that this kind of centralized AI control layer will be critical as China pushes robots deeper into factories, logistics hubs, and smart cities.

Key Features:

- Focus on a hardware-agnostic “universal brain” for multiple robot types

- Emphasis on real-time perception + large models for navigation and manipulation

- Target sectors include manufacturing, logistics, and smart infrastructure

How It Works:

Boundless Power is building a cloud-style architecture where robot “bodies” connect via standard interfaces to a central AI stack that handles mapping, decision-making, and motion planning. Over time, data from thousands of robots can be pooled to continuously improve the shared “brain.”

2) XPeng’s “Terminator” Moment: Iron Humanoid Goes Viral

XPeng’s Iron humanoid goes full Terminator on stage | Weekly Robotics News | The Bolt and the Byte

Videos shared by XPeng and tech media show Iron walking with a highly human-like, almost catwalk-style gait, performing martial-arts-style movements, and reacting smoothly to balance changes. Under the “skin,” the robot features dense packaging of motors, linkages, power electronics, and a spine-like central structure. XPENG+1

Key Features:

- Humanoid robot with bionic spine, synthetic full-body skin, and 82 degrees of freedom

- Hands with 22 degrees of freedom per hand for fine manipulation

- Onboard compute reportedly around 2,250 TOPS, targeting complex perception and motion control

- Skin can be removed to demonstrate mechanical authenticity after online skepticism

How It Works:

XPeng combines high-performance actuators with a stacked AI system that fuses vision, language, and task planning, enabling Iron to interpret gestures or verbal instructions and translate them into coordinated full-body motion.

Why It Matters:

Iron’s demo underscores how fast Chinese EV and robotics players are moving from concept art to convincing full-body motion — and highlights a looming competition with Tesla, Figure, and others for the first widely deployed general-purpose humanoid.

Current Status: Prototype stage, with XPeng promising an open SDK and a developer ecosystem around Iron.

Sources: Futurism/Yahoo; XPeng press release; social video.

3) Under the Skin: NotebookCheck’s Deep Dive into Iron’s Hardware

Inside XPeng’s Iron: high-tech actuators and dense robotics packaging | Weekly Robotics News | The Bolt and the Byte

Story

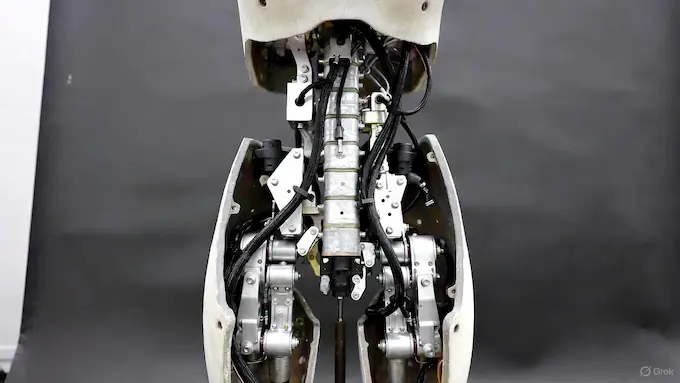

This week’s robotics industry highlight includes NotebookCheck’s teardown coverage of Iron’s viral demo, focusing less on the spectacle and more on what’s actually inside the robot once the “Terminator” skin is peeled back.

High-resolution photos reveal compact servo modules, carefully routed cabling, and a central backbone that looks closer to a high-end industrial machine than a lab prototype. The article notes that the density and finish of the components suggest XPeng is designing with scalability and manufacturability in mind rather than one-off research hardware.

Key Features:

- Exposed actuators and joints with neat cable routing and structural bracing

- Electronics placed along the spine and torso for weight distribution

- Modular construction hinting at serviceability and potential mass production

- Design suggests lessons borrowed from EV and automotive manufacturing

How It Works:

By embedding actuators close to the joints and centralizing power and compute in the torso, Iron’s design reduces inertia in the limbs and enables smoother whole-body motion — the same principles used in EV powertrain packaging.

Why It Matters:

The teardown reinforces that Iron isn’t just a show bot: it’s built like hardware intended to scale, strengthening the case that humanoids are moving rapidly from R&D curiosities to serious products in development.

Current Status: Media analysis of early prototypes; XPeng is courting developers and investors with behind-the-skin transparency.

Sources: NotebookCheck; XPeng; syndicated Futurism coverage.

4) AIdol’s Fall: When a Russian Humanoid AIdol Hits the Floor

AIdol’s on-stage fall shows the hard truth of humanoid AI | Weekly Robotics News | The Bolt and the Byte

Story

Also in the world of robotics, TokenRing’s longform analysis uses the on-stage fall of Russia’s humanoid robot “AIdol” in Moscow on November 11 as a snapshot of where humanoid AI stands in late 2025: impressive demos, but still fragile in the physical world.

The article contrasts AIdol’s tumble with rapid strides from XPeng’s Iron, Leju’s “Kuafu” relay robot, Tesla Optimus, Boston Dynamics’ fully electric Atlas, and Figure AI’s factory deployments. Together they show a field where robots can dance, sprint, and handle factory tasks, yet still struggle with balance, safety, and reliability in unscripted conditions.

Key Features:

- AIdol’s public fall during a high-profile Moscow event

- Survey of leading humanoids: Iron, Kuafu, Optimus, Atlas, Figure 02, Unitree H2/G1

- Discussion of pricing pressure, with robots like Unitree H2 targeting sub-$30k price points

- Overview of massive venture funding into humanoid startups worldwide

How It Works:

TokenRing frames humanoids as embodied large-model systems, combining generative AI, vision-language-action models, and reinforcement learning to map human demonstration into robot behavior — but notes that translating perfect lab demos into real-world robustness remains extremely hard.

Why It Matters:

AIdol’s fall is less a failure and more a stress test for public expectations. The piece argues we are entering a “crucible phase” where robots will increasingly share human spaces, and every stumble will be scrutinized — even as deployments in factories, logistics, and eldercare quietly ramp up.

Current Status: AIdol remains a symbolic cautionary tale while global humanoid deployments move from dozens to hundreds and soon thousands of units. Sources: TokenRing (via WRAL/FinancialContent); various vendor announcements.

5) Factory Robot Demand Has Doubled in a Decade

Factory robot demand doubles in ten years, IFR finds | Weekly Robotics News | The Bolt and the Byte

Story

This automation development is particularly interesting: the International Federation of Robotics (IFR) reports that industrial robot installations hit 542,000 units in 2024, more than twice the number installed a decade ago. The total stock of industrial robots in operation has climbed to about 4.66 million units worldwide.

Asia dominates robot adoption, accounting for 74% of new deployments in 2024, with China alone responsible for 54% of global installations and over 2 million robots now in operation. Europe and the Americas trail but still post historically high installation figures, even with a short-term dip driven by macro-economic uncertainty.

Key Features:

- 542k robots installed in 2024; annual installations above 500k for four straight years

- Global operating stock: 4.664 million robots, up 9% year-on-year

- Asia: 74% of 2024 installations; China 54% and rising robot density

- IFR projects installations to surpass 700k units per year by 2028 IFR International Federation of Robotics

How It Works:

IFR’s World Robotics 2025 report aggregates data from robot manufacturers and integrators worldwide, providing one of the most trusted baselines for understanding where industrial automation is actually happening, sector by sector and region by region.

Why It Matters:

For readers of Weekly Robotics News, IFR’s numbers confirm that robots are no longer “future tech” — they’re now standard equipment in automotive, electronics, logistics, and more. The growth forecast suggests a long runway for both industrial arms and next-gen humanoids entering factories later this decade.

Current Status: IFR forecasts about 6% growth in installations in 2025, with a path to 700k+ units annually by 2028.

Sources: IFR World Robotics 2025 report.

6) Apple Robotics Could Rival the App Store by 2040

Apple’s future robotics business could match today’s App Store | Weekly Robotics News | The Bolt and the Byte

Story

On the AI and robotics front, Morgan Stanley analysts quoted by AppleInsider argue that “Apple Robotics” could generate around $130–133 billion a year by 2040 — on par with today’s App Store revenue and potentially Apple’s second-largest business after the iPhone.

The bank expects Apple’s first step to be a motorized tabletop hub around 2027 that can track users, move slightly, and act as a physical anchor for Apple Intelligence, before scaling up to more capable home and perhaps humanoid robots. Over time, Apple could capture about 9% of a projected $5 trillion embodied-AI market, with subscription services layered on top of the hardware.

Key Features:

- Forecast: ~$133B/year in robotics revenue by 2040 under baseline scenario

- First product: a tabletop robot hub expected around 2027

- Long-term roadmap: from small home robots to humanoid and industrial systems

- Leverages Apple’s strengths in silicon, hardware-software integration, and services

How It Works:

Analysts see Apple Intelligence as the bridge: multimodal perception and reasoning on-device, extended to physical embodiments that move around the home. Apple could reuse expertise from Project Titan (the shelved car project) and its Daisy recycling robot for robotics hardware and manufacturing.

Why It Matters:

If Apple enters robotics seriously, it would reshape consumer expectations around safety, privacy, and reliability in home robots — and intensify competition with Tesla, Chinese humanoid startups, and traditional robot makers moving toward the home.

Current Status: No official product yet; Morgan Stanley’s note is based on hiring trends, patents, and Apple’s historic pattern of entering new categories late but decisively.

Sources: AppleInsider; Morgan Stanley analysis.

7) Noetix’s Bumi: A Humanoid Cheaper than an iPhone

Noetix Bumi undercuts humanoid prices, rivaling an iPhone 17 Pro Max | Weekly Robotics News | The Bolt and the Byte

Story

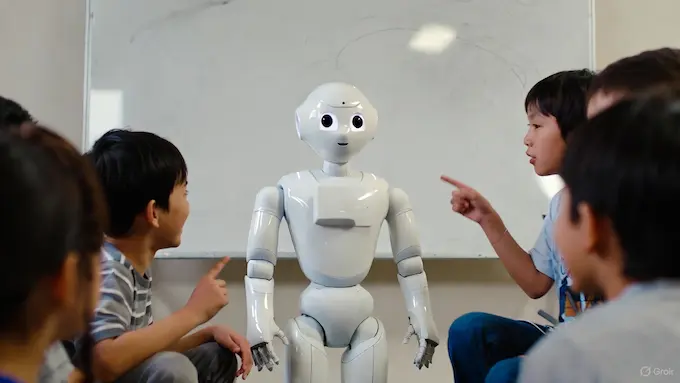

A key update from the robotics sector comes from Noetix Robotics, which has revealed how its 94-cm humanoid Bumi hits a price tag of RMB 9,998 — roughly the cost of an iPhone 17 Pro Max in China — after raising nearly RMB 300 million in Pre-B funding led by Vertex Ventures.

Bumi is aimed at education and family entertainment, not heavy physical work. TechNode reports that over 100 units sold in the first hour, with the first 500 gone within two days on JD.com, signalling strong early demand for a “consumer-grade” humanoid that can talk, gesture, and be programmed, instead of just sitting in a lab. T

Key Features:

- Price: RMB 9,998 (~US$1,380), roughly high-end smartphone level

- Height: 94 cm, intentionally below full adult size to avoid the uncanny valley

- Weight: ~12 kg thanks to composite structures and targeted metal reinforcement

- Deep local supply chain with nearly all components sourced in China

How It Works:

Noetix keeps costs low through vertical integration (own boards and motor drivers), material optimization (lighter structure enables smaller motors and batteries), and a domestic component ecosystem. Bumi also hooks into JD.com’s Joy Inside 2.0 platform and exposes programming interfaces for schools and developers.

Why It Matters:

Bumi signals the start of a cost-reduction era in humanoid robotics, showing how Chinese startups might get humanoids into homes and classrooms years before Western rivals hit similar price points.

Current Status: Pre-B funding closed; ramp-up toward 1,000 units per month by late 2025 is planned.

Sources: TechNode; Noetix Robotics.

8) The Battle to Build Humanoids Will Intensify

The humanoid arms race heats up into 2026 | Weekly Robotics News | The Bolt and the Byte

Story

Another significant robotics story this week centers on The Economist’s “The World Ahead” piece, which predicts that the battle to build humanoid robots will intensify as we move into 2026, with Tesla, Chinese firms like XPeng and Noetix, and Western players such as Figure, Agility, and Boston Dynamics all vying for early lead.

Key Features:

- Convergence of falling hardware costs + powerful AI models

- National strategies (China, US, Europe) prioritizing humanoids for productivity and aging-population challenges I

- Early deployments in automotive, warehousing, and light manufacturing

- High risk of public “fails” as prototypes are exposed to messy environments

How It Works:

The emerging playbook: start with tightly scoped factory tasks (moving materials, machine tending), rely heavily on teleoperation and human demonstrations at first, then gradually increase autonomy as models improve and data piles up.

Why It Matters:

For readers of Weekly Robotics News, this isn’t just hype: it’s a signal that robotics careers, investments, and regulations will increasingly orbit around embodied AI — robots that can walk, lift, and interact in the same spaces we do.

Current Status: Mixed: dazzling demos (Optimus, Iron) co-exist with staged falls (AIdol) and robots that still rely on safety rigs and human guidance.

Sources: The Economist (World Ahead 2025); IFR; TokenRing.

9) Poland’s New Recon Robot for Tough Border Missions

Poland fields a new Israeli-built recon robot for high-risk operations | Weekly Robotics News | The Bolt and the Byte

Story

This development in robotic technology comes from NextGenDefense, which reports that Poland is procuring a new reconnaissance robot from an Israeli manufacturer to support troops in high-risk environments. The small, tracked platform is designed for urban combat, border security, and bomb-squad style inspections, letting operators scout dangerous areas from a safe distance.

Equipped with cameras, lights, and other sensors on a mast, the robot can be tossed or driven into buildings, tunnels, or rough terrain, sending back live video and telemetry to operators wearing ruggedized control tablets. The acquisition fits a broader trend of European militaries investing in unmanned ground vehicles for ISR (intelligence, surveillance, reconnaissance) roles.

Key Features:

- Compact, tracked reconnaissance robot built by an Israeli defense robotics company

- Day/night cameras and communications link for remote operation

- Intended for border missions, urban operations, and explosive-threat checks

- Expands Poland’s portfolio of unmanned systems alongside drones

How It Works:

Operators deploy the robot ahead of manned patrols; it sends real-time video and sensor feeds, helping identify threats like ambushes, IEDs, or hidden personnel. If damaged, the loss of a robot is far more acceptable than risking a human team.

Why It Matters:

While much attention goes to humanoids, the steady spread of small recon robots shows how robotics is already reshaping ground operations and border security in subtle but significant ways.

Current Status: Initial procurement approved; fielding is expected with specialized Polish units over the coming months.

Sources: NextGenDefense.

10) Capgemini & Orano’s Humanoid Robot for Nuclear Work

Capgemini and Orano test humanoid robots for nuclear facilities | Weekly Robotics News | The Bolt and the Byte

Story

Continuing our robotics coverage, Capgemini and French nuclear group Orano have teamed up on a project to deploy an AI-enabled humanoid robot inside nuclear facilities, supporting inspection and maintenance in environments where human exposure to radiation and contamination must be minimized.

According to AI Magazine, the robot integrates Capgemini’s AI, digital twin, and remote-operation stack with Orano’s domain expertise, allowing operators to pilot the humanoid or assign semi-autonomous tasks such as valve checks, gauge readings, and simple manipulation in areas normally accessible only with heavy protective gear.

Key Features:

- Humanoid platform adapted for nuclear-grade personal protective tasks

- Uses AI-driven perception, digital twins, and remote operation for planning and control

- Intended for inspection, sampling, and light maintenance inside restricted zones

- Aims to help with skills shortages and safety compliance in nuclear operations

How It Works:

Operators work from a control room, seeing through the robot’s cameras and using haptic or joystick controls; over time, more actions can be scripted or automated using AI models trained on repeated procedures inside digital twins of the plant.

Why It Matters:

Nuclear sites are a natural early home for humanoids: dangerous, structured, and highly regulated. Success here could make the case for humanoids in other harsh or remote industrial environments.

Current Status: Pilot/demo phase with testing at Orano facilities in France.

Sources: AI Magazine / Orano–Capgemini announcement.

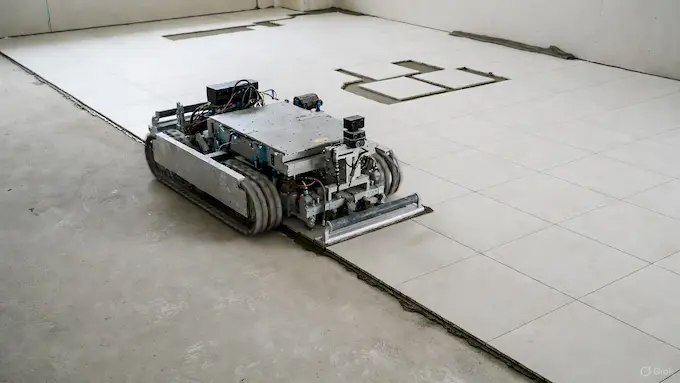

11) Partner Robotics Raises Series A for Building & Tiling Robots

Partner Robotics lands Series A to scale construction robots | Weekly Robotics News | The Bolt and the Byte

Story

This week also saw news in automation from Partner Robotics, a Beijing-based company building floor-tiling and construction robots, which has raised an eight-figure RMB Series A round. Reports from FinSMEs and PropTechBuzz put the company’s total funding around RMB 100 million (~US$14M) since its founding in 2023.

Partner Robotics offers robots like the P900 floor-tile paving robot, combined with a multi-sensor perception system and cloud-based simulation platform that lets contractors plan tiling jobs digitally and then execute them through autonomous or semi-autonomous robots on site.

Key Features:

- Series A led by China Growth Capital, with Cowin Capital and Redpoint China participating

- Around RMB 100M total funding since 2023

- Robots specialized in floor tiling and building finishing tasks

- Cloud simulations and multi-sensor perception to align digital blueprints with real-world floors

How It Works:

Contractors upload plans to Partner Robotics’ platform; robots then measure, mark, and lay tiles according to the design, using vision and laser sensing to maintain alignment and adjust for real-world irregularities.

Why It Matters:

Construction is a huge, under-automated sector; if Partner Robotics can reliably automate tiling and similar jobs, it could reduce on-site labor demands and improve consistency—especially in markets facing aging labor forces and housing booms.

Current Status: Fresh Series A closed; company plans to deploy robots on construction sites worldwide, starting in China and expanding abroad via partners.

12) Stereotaxis’ New Endovascular Robot Wins FDA Clearance

Stereotaxis Genesis-class surgical robot gets FDA 510(k) nod | Weekly Robotics News | The Bolt and the Byte

Story

A noteworthy robotics trend we’re tracking is inside the cath lab: Stereotaxis has received FDA 510(k) clearance for its next-generation endovascular surgical robot, a magnetic navigation system designed to steer catheters and guidewires through blood vessels with more precision and less radiation exposure.

The new platform builds on Stereotaxis’ established magnetic navigation technology but promises a smaller footprint, improved ergonomics, and upgraded software, helping hospitals modernize interventional suites while enabling remote operation from a shielded control room.

Key Features:

- FDA clearance for a next-gen robotic magnetic navigation system

- Aims to reduce radiation exposure by allowing doctors to work away from the X-ray beam

- Provides fine control of catheters for cardiology and neurovascular procedures

- Tighter integration with imaging and hospital IT systems

How It Works:

Large magnetic assemblies around the patient generate controlled fields that gently steer specially designed catheters; clinicians command the system from a console, using joysticks and software rather than standing next to the patient in heavy lead.

Why It Matters:

It’s a reminder that some of the most mature robots aren’t humanoids but specialized medical systems quietly improving patient outcomes and clinician safety.

Current Status: FDA-cleared for clinical use in the United States; commercial rollout now depends on hospital purchasing cycles.

Sources: Diagnostic and Interventional Cardiology (dicardiology).

13) China’s Robots Go Global

China’s robots expand their global footprint in 2024 | Weekly Robotics News | The Bolt and the Byte

Story

This report from the automation industry highlights how Chinese robots are rapidly spreading worldwide, not just in factories but in food delivery, healthcare, logistics, and consumer services. A People’s Daily article notes that Chinese robots in 2024 were increasingly visible overseas, supporting smart manufacturing and services with relatively low costs and strong performance.

Complementing this, data from IFR and China Daily show that since 2021 China has installed more than half of the world’s new industrial robots, averaging around 280–290k units per year, and reaching a robot density of about 470 robots per 10,000 manufacturing workers—second only to South Korea.

Key Features:

- Chinese robots active in delivery, warehousing, healthcare, and home services abroad

- Over 2 million industrial robots operating in China, the largest stock globally

- Robot density of 470 per 10,000 workers, up nearly 4x since 2017

- Government strategy ties robots to new growth sectors such as EVs, solar, and batteries

How It Works:

China is leveraging a dense manufacturing ecosystem to produce robots and components domestically, driving down costs while using AI and smart-factory initiatives to integrate those robots across supply chains.

Why It Matters:

For global readers, this shift means many of the robots arriving in factories, warehouses, and even restaurants worldwide will likely be designed and built in China, influencing pricing, standards, and competitive dynamics for years to come.

Current Status: China has been the world’s largest industrial robot market for 12 consecutive years, and growth is expected to continue through at least 2028.

Sources: People’s Daily; China Daily; IFR; industry analyses.

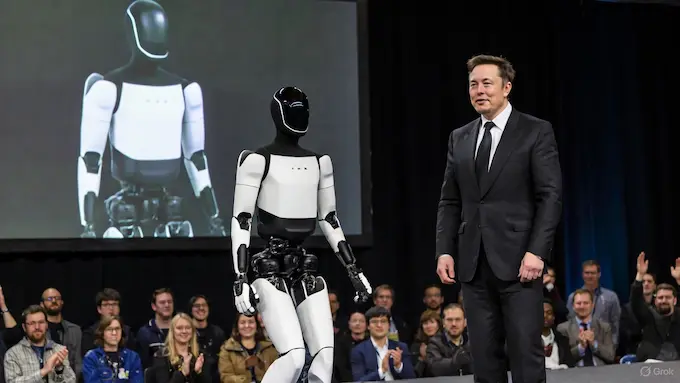

14) Tesla’s Optimus Dances—and Trains—Its Way into the Spotlight

Tesla’s Optimus shows lifelike dance moves at 2025 meeting | Weekly Robotics News | The Bolt and the Byte

Story

Our next robotics dispatch covers Tesla’s Optimus humanoid, which grabbed headlines again after Elon Musk danced alongside the robot to celebrate a record-breaking CEO compensation package, with Optimus matching his moves in a widely shared video.

Behind the scenes, reporting from Business Insider describes workers in a glass-walled Tesla lab spending hours wearing camera-equipped helmets and heavy backpacks to capture everyday actions—lifting cups, wiping tables, pulling curtains—to teach Optimus via imitation learning. The work is physically demanding and sometimes requires teleoperating robots strapped into safety rigs to avoid falls.

Key Features:

- Viral video of Optimus dancing with Musk after shareholder approval of a huge pay package

- Inside the lab, workers perform repetitive tasks to generate motion data for training

- Optimus is still often supported by a gantry rig and can tumble during complex maneuvers

- Tesla is planning a larger Gen 3 production line and pilot deployments in factories

How It Works:

Tesla is shifting from motion-capture suits to a camera-only data-collection approach, using multi-view human demonstrations to train models that map perception to whole-body robot motion. Teleoperation fills gaps during investor demos and tricky tasks.

Why It Matters:

Optimus sits at the intersection of celebrity tech spectacle and hard industrial R&D: the dancing robot clips drive hype, but the real story is whether Tesla can turn that attention into reliable, factory-grade humanoids that justify their massive investment.

Current Status: Optimus prototypes are active at Tesla’s engineering HQ, with a pilot production line planned and early internal deployments in development. Sources: Blockchain.News topic (via other media), Financial Express, Business Insider, Tesla event coverage.

15)Claude’s “Project Fetch” helps a robot dog learn new tricks

Anthropic’s Project Fetch tests whether Claude can train a robot dog | Weekly Robotics News | The Bolt and the Byte

Story

Anthropic’s new study, Project Fetch: Can Claude train a robot dog?, divided eight in-house researchers—none of them robotics specialists—into two teams: one with access to Claude and one without. Both teams had to program a quadruped “robodog” to fetch a beach ball through three escalating task phases.

- Phase One: Use the manufacturer’s controller to guide the robot to bring the ball back—just to learn the hardware.

- Phase Two: Connect laptops to the robot, tap into its video and lidar sensors, write custom control software, and manually retrieve the ball.

- Phase Three: Write code so the robot could autonomously detect and fetch the ball without human steering.

According to Anthropic, Team Claude completed more tasks and did them faster. For tasks both teams finished, the Claude-assisted group worked in about half the time, and only Team Claude made substantial progress on full autonomous fetch—getting the robot to locate, navigate toward, and move the ball, even if it didn’t quite master the final pickup.

Claude’s biggest edge was in connecting to the hardware and sensors: figuring out how to talk to the robot over the network, stream data, and issue commands. Team Claude also struggled less with misleading online docs and managed to pull useful lidar data much sooner than the control group.

There were trade-offs. Anthropic notes that Team Claude wrote about nine times more code, which enabled richer tools (like a smooth video-based controller) but also tempted them into “side quests.” Meanwhile, the Claude-less team sometimes moved faster on specific programming subtasks and may have walked away with a deeper mental model of the libraries they used.

Team dynamics told their own story: Claude-less researchers expressed more negative emotions and confusion in their recorded conversations, while Team Claude generally seemed happier—though both groups felt pressure as the clock ran down.

Wired reports that the robot itself was a Unitree Go2 quadruped, a roughly $16,900 platform typically used for industrial inspections and security patrols, which made this a realistic testbed for how AI might help operate robots in noisy real-world conditions.

Key Features:

- 8 Anthropic researchers, split into Team Claude vs Team “Claude-less.”

- Quadruped Unitree Go2 robot dog; tasks centered on fetching a beach ball over three phases.

- Team Claude completed 7/8 tasks vs 6/8 for the control team and finished shared tasks in about half the time.

- Claude was especially helpful for connecting to hardware, streaming sensor data, and building better controllers.

- Emotional analysis of transcripts showed more frustration and confusion on the Claude-less team.

Why It Matters:

For Weekly Robotics News, Project Fetch is a clean case study of AI uplift in robotics: with an AI coding assistant, non-experts can do surprisingly complex robot work in a day. Anthropic emphasizes that uplift often comes before autonomy—what AI helps humans do today, it may do alone tomorrow—which makes this kind of evaluation important for tracking when models might directly control robots in warehouses, homes, or even labs.

Current Status:

Project Fetch is just one one-day experiment with a small sample size, and Anthropic is explicit about its limitations. For now, Claude helps humans bridge the digital-physical gap; it doesn’t yet autonomously design and run full robotics pipelines. But Anthropic says it will keep monitoring robotics-related capabilities as part of its Responsible Scaling Policy, watching for signs that models can reliably interact with previously unknown hardware.

Source: Anthropic – “Project Fetch: Can Claude train a robot dog?”; WIRED – “Anthropic’s Claude Takes Control of a Robot Dog.”

What are the main trends highlighted in this week’s Weekly Robotics News?

This week’s Weekly Robotics News spotlights three big trends: the rapid rise of humanoid robots (XPeng Iron, Tesla Optimus, Noetix Bumi, Russia’s AIdol), the push toward embodied AI and “robot brains” (Boundless Power, China’s embodied-AI strategy, Anthropic’s Project Fetch), and the spread of robots into high-stakes industries like nuclear power, medicine, construction, and defense.

Why is China such a major focus in these robotics stories?

Multiple stories show China becoming a central hub for robotics: factory robot density has surged, robotics revenue is growing nearly 30% year-on-year, and companies like Boundless Power, Noetix Robotics, and Partner Robotics are building everything from humanoids to tiling robots. Together they illustrate how China is trying to lead both in robot deployment and in the embodied AI that makes future humanoids useful.

How close are humanoid robots like XPeng Iron, Tesla Optimus, AIdol and Bumi to real-world work?

Humanoids in this week’s roundup are at different stages. XPeng’s Iron and Tesla’s Optimus are advanced prototypes doing impressive demos but still need safety rigs, heavy human training, and careful calibration. Noetix Bumi is a smaller, cheaper humanoid aimed at education and families, not heavy labor. Russia’s AIdol, which fell on stage, shows how fragile public demos can still be. Overall, they’re getting closer, but widespread, unsupervised work in homes and factories is still in the early pilot phase.

What does “embodied AI” mean in the context of these news stories?

“Embodied AI” refers to AI systems that don’t just chat or generate images, but control physical bodies—like humanoids, robot dogs, or industrial machines. In this week’s news, embodied AI shows up in Boundless Power’s “universal robot brain,” China’s world-model ambitions, Anthropic’s Project Fetch with a robot dog, and the global humanoid race. The goal is AI that can see, reason and act in the messy physical world, not just on a screen.

How are AI assistants like Claude actually helping with robotics today?

Anthropic’s Project Fetch shows that an AI assistant like Claude can already boost human teams working with robots: it helped non-experts connect to a Unitree robot dog, read its sensors, and write control code faster than a team working without it. In practical terms, AI assistants are starting to act like robotics copilots—speeding up integration and debugging today, and paving the way for more autonomous robot control tomorrow.

Where do the robotics stories in Weekly Robotics News come from?

We curate stories from a mix of reputable tech, business, science and industry sources, then add context, key takeaways, and “why it matters” sections so readers can quickly understand the impact on robotics, automation, and embodied AI.