Table of Contents

1. Amazon’s Robotics Chief Wants to Automate Every “Menial, Mundane” Job

Inside Amazon’s plan to hand the boring work to machines | Weekly Robotics News | The Bolt and the Byte

Story

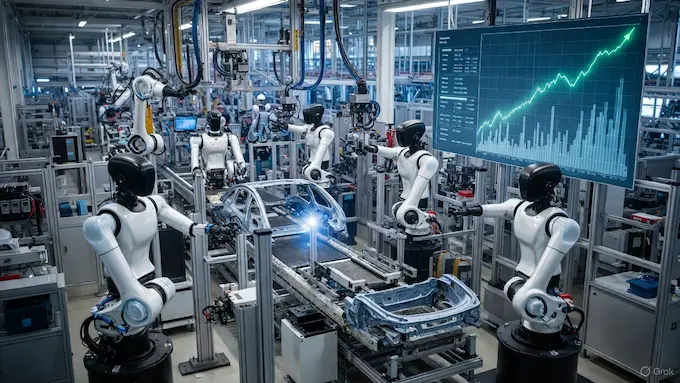

Amazon robotics chief Tye Brady says the company’s long-term goal is for robots to take over every “menial, mundane and repetitive” task in its warehouses, from lifting heavy totes to moving pallets and sorting packages. He argues that automation will remove dull and dangerous jobs while opening up more skilled roles in maintenance, safety, and operations. Fox Business

Amazon already runs more than a million robotic systems across its network and is deploying AI-powered arms and mobile robots that can handle a growing share of inventory. Brady insists this doesn’t mean fewer people, but a shift in what people do. For this weekly robotics news update, the key question is whether Amazon’s “robots do the grunt work, humans do the thinking” vision becomes the template for global logistics.

Key details

- Goal: automate all repetitive warehouse tasks over time

- Fleet: over 1M robotic systems already deployed worldwide Fox Business

- Message: robots as co-workers, not direct headcount cuts

2. Tether Considers Up to $1B Bet on Neura Robotics’ Humanoid Factory Workers

Stablecoin giant eyes German humanoids as the next big automation trade | Weekly Robotics News | The Bolt and the Byte

Story

Stablecoin issuer Tether is reportedly in talks to invest up to $1 billion over several years in German startup Neura Robotics, which builds “cognitive robots” for factories, logistics, and care settings. CoinDesk The deal would fund a new robotics campus in Germany and scale production of Neura’s humanoid and collaborative robots.

Neura says its machines can perceive their surroundings, understand natural language, and work safely alongside people, targeting tasks like inspection, pick-and-place, and machine tending. For this weekly robotics news edition, the potential tie-up shows how crypto cash is starting to flow into real-world automation, not just digital assets.

Key details

- Potential investment size: up to $1B over time CoinDesk

- Neura builds cognitive humanoids and cobots for industry

- Plan includes a major new robotics site in Germany

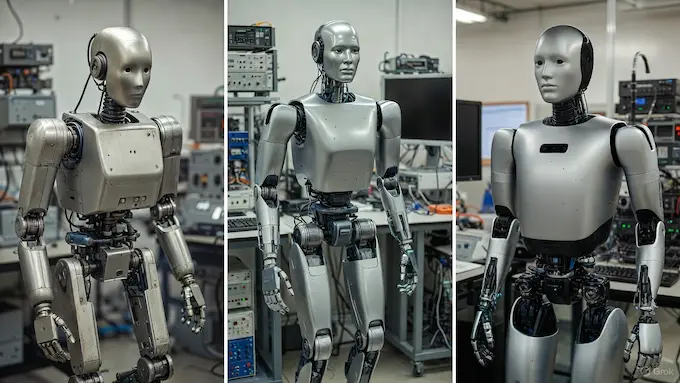

3. UBTECH Claims First Large-Scale Delivery of Humanoid Factory Workers

Walker S2 humanoids roll into real industrial jobs | Weekly Robotics News | The Bolt and the Byte

Story

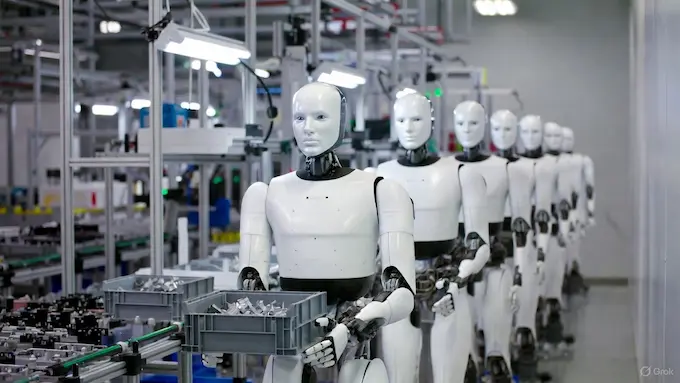

Chinese robotics maker UBTECH says it has completed what it calls the world’s first large-scale delivery of humanoid robots into factories. Its Walker S2 humanoids are being deployed at multiple industrial sites to move materials, perform inspections, and help run 24/7 operations alongside traditional automation. Interesting Engineering

The robots are designed to walk, manipulate objects, and operate some tools, with AI models helping them understand their environment. In this weekly robotics news roundup, UBTECH’s rollout is a concrete step toward humanoids leaving the demo stage and handling repetitive line work in real production environments.

Key details

- Dozens to hundreds of Walker S2 units deployed to factories in China Interesting Engineering

- Tasks: material handling, inspection, and support for continuous operations

- UBTECH positions this as the first “large delivery” of humanoid workers

4. XPeng’s ‘Iron’ Humanoid Has Its Viral “Terminator” Moment

China’s XPeng shows off Iron walking on stage with exposed actuators | Weekly Robotics News | The Bolt and the Byte

Story

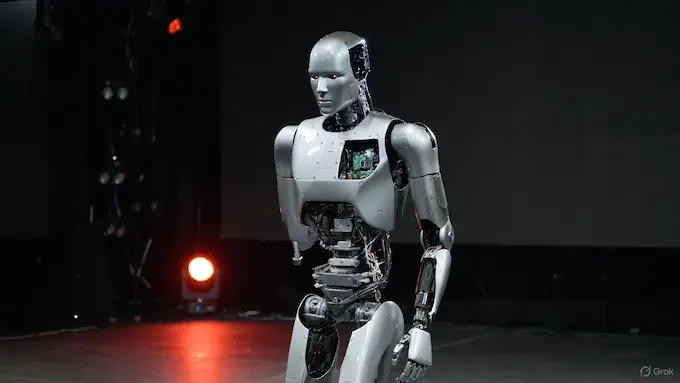

XPeng released dramatic footage of its Iron humanoid walking across a dark stage with part of its arm “skin” peeled back to reveal dense silver actuators and cables. The demo immediately drew “Terminator” comparisons online, but XPeng says Iron is aimed at manufacturing and logistics work, not sci-fi chaos. Futurism+1

Iron is designed as a general-purpose humanoid that can navigate complex spaces and handle boxes or tools, using large AI models for perception and motion. In this weekly robotics news entry, Iron’s slick presentation highlights how Chinese carmakers are racing not just on EVs, but on humanoid robotics that could one day work in their own factories.

Key details

- Iron humanoid revealed in a stage demo with exposed mechanics Futurism+1

- Target use cases: factory and warehouse tasks

- XPeng positions robots as part of its broader “AI + EV + robotics” ecosystem

5. Haier and INDEMIND Team Up on an Embodied-AI Home Robot Ecosystem

From TVs to service bots: Haier pushes deeper into smart-home robotics | Weekly Robotics News | The Bolt and the Byte

Story

Appliance giant Haier is partnering with AI startup INDEMIND to build a “home embodied intelligence ecosystem” that links smart appliances with mobile robots. The companies plan service robots that can patrol homes, deliver items, and interact with Haier TVs, air conditioners, and other devices through a shared AI brain. 36Kr

INDEMIND brings perception and navigation software, while Haier contributes massive distribution and hardware platforms. For this weekly robotics news roundup, the message is clear: home robots won’t live alone; they’ll be tightly integrated with smart-home hardware and cloud services from day one.

Key details

- Partnership focuses on embodied AI for home service robots 36Kr

- Robots expected to interact with Haier smart appliances and screens

- Long-term goal: full-home “robot + appliance” coordination

6. This Home Robot Clears Your Table and Loads the Dishwasher

Teleoperated today, autonomous tomorrow? | Weekly Robotics News | The Bolt and the Byte

Story

A new home robot showcased in Wired demos can pick up plates, carry them from the dining table, and load them into a dishwasher, using a mobile base and multi-jointed arm. For now, many of the hardest motions rely on remote human teleoperators, who control the robot through VR-style interfaces while the system gradually learns from their demonstrations. WIRED

The company behind the robot pitches it as a path to long-term independence for elderly or disabled users, starting with teleoperation and moving toward more autonomy as AI improves. In this weekly robotics news update, the robot is a glimpse of how domestic service bots might actually arrive: first as human-in-the-loop helpers, then as semi-autonomous chore machines.

Key details

- Robot can carry dishes, load dishwashers, and tidy surfaces WIRED

- Many tasks currently driven by remote human operators

- Long-term goal is a general home helper for daily chores

7. “Artificial Spacetimes” Help Tiny Microrobots Swim in Crowded Fluids

New physics-inspired control tricks for medical-scale robots | Weekly Robotics News | The Bolt and the Byte

Story

Researchers have demonstrated microrobots that navigate crowded, viscous fluids — like blood or mucus — by exploiting “artificial spacetimes,” where clever control patterns change how the robots experience their environment. Instead of brute-forcing their way through thick liquids, these bots use programmed oscillations and interactions with surrounding particles to move efficiently. Tech Xplore

The work is still early-stage but could eventually help microrobots deliver drugs, perform targeted therapy, or inspect tight industrial channels. For our weekly robotics news coverage, it’s a reminder that some of the most radical robotics advances are happening at scales you can barely see.

Key details

- Microrobots use physics-inspired control to move through dense fluids Tech Xplore

- Applications: targeted drug delivery, micro-surgery, and micro-inspection

- Demonstrations show improved mobility in complex environments

8. Parallax Worlds Raises $4.9M to Stress-Test Robot Factories in Simulation

Digital twins meet industrial robots | Weekly Robotics News | The Bolt and the Byte

Story

Parallax Worlds has raised about $4.9 million in seed funding to build simulation tools that let manufacturers “pre-debug” robot-heavy production lines before any hardware is installed. Its platform can model robots, conveyors, and humans in a virtual factory, then run thousands of scenarios to identify bottlenecks, safety issues, and failures. SiliconANGLE+1

By the time real hardware arrives, engineers can deploy a plan that’s already been attacked from every angle in software. In this weekly robotics news roundup, Parallax Worlds represents a shift toward simulation-first robotics: testing factories like video game levels before switching on real motors.

Key details

- Seed round: roughly $4.9M to build industrial robot simulations SiliconANGLE+1

- Customers include large automotive and logistics firms

- Goal: reduce commissioning time and costly integration mistakes

9. Google DeepMind’s Gemini Robotics 1.5 Pairs a “Brain” Model With a “Body” Model

Agentic AI for real-world robots | Weekly Robotics News | The Bolt and the Byte

Story

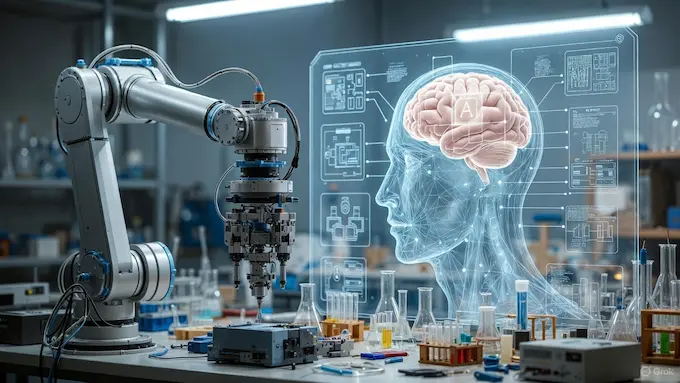

Google DeepMind has introduced Gemini Robotics 1.5 and Gemini Robotics-ER 1.5, a two-part system where one model handles language and reasoning (the “brain”) while another controls perception and movement (the “body”). Facebook Together, they let robots interpret natural language instructions, plan multi-step tasks, and then execute motions with arms and mobile bases.

Demo videos show robots tidying up, handling objects, and adapting to small changes in their environment instead of following rigid scripts. In this weekly robotics news story, Gemini Robotics is a sign of where embodied AI is going: not one giant model that does everything, but coordinated specialist models that reason and act together.

Key details

- Two-model architecture: high-level reasoning + low-level control Facebook

- Designed for long-horizon, multi-step robot tasks

- Shows how foundation models are being tailored to embodied agents

10. Elon Musk Predicts AI and Humanoid Robots Will Make Work “Optional”

Tech billionaire sees poverty eliminated in 10–20 years | Weekly Robotics News | The Bolt and the Byte

story

Speaking at the US–Saudi Investment Forum, Elon Musk said advanced AI and humanoid robots will eventually “eliminate poverty” and make work optional within 10–20 years. Anadolu Ajansı He compared future jobs to hobbies: something people do for fulfillment, not survival. Musk also announced a partnership between his xAI startup and Saudi-backed firm Humain to build a major data center in the kingdom powered by up to 500 megawatts. Anadolu Ajansı

In this weekly robotics news piece, Musk’s timeline is highly optimistic and assumes that society can manage the economic and political upheaval that mass automation would bring. But his comments underline a growing belief among tech leaders that humanoids won’t just work in factories—they’ll reshape the global labor market.

Key details

- Prediction: poverty eliminated and work “optional” in 10–20 years Anadolu Ajansı

- xAI and Humain planning a huge GPU data center in Saudi Arabia

- Raises big questions about redistribution, policy, and social safety nets

11. Dennis Hong’s Humanoid Journey: From CHARLI to the Dream Robot Butler

UCLA roboticist reflects on 20 years of humanoid R&D | Weekly Robotics News | The Bolt and the Byte

Story

UCLA professor Dennis Hong, one of the world’s best-known humanoid roboticists, looked back on two decades of building legged robots—from early platforms like CHARLI and THOR to the soccer-playing ARTEMIS robot. 36Kr His original dream was a “robot butler” that could cook, clean, and help at home, but he now says that vision has proven far harder than expected.

Hong’s lab continues to push on locomotion, balance, and dynamic movement, while acknowledging that everyday manipulation and reliability remain huge challenges. In this weekly robotics news item, his career arc captures the field’s mood: we’re finally seeing humanoids move well, but turning them into safe, general home helpers is still a long-term project.

Key details

- Built multiple generations of humanoids including CHARLI and ARTEMIS 36Kr

- Focus areas: dynamic walking, running, and balance

- Robot butler goal remains a north star, not a shipped product

12. Boston Dynamics’ Spot Becomes a Controversial Police Tool

From dancing dog to SWAT team asset | Weekly Robotics News | The Bolt and the Byte

Story

Boston Dynamics’ four-legged robot Spot is increasingly being deployed by police and bomb squads in the US and Canada. According to reporting shared with Bloomberg, more than 60 SWAT teams and bomb units now use Spot for armed standoffs, hostage situations, and hazardous materials incidents, where sending a human (or a real dog) could be deadly. NZ Herald

Supporters say robot dogs keep officers safer and can defuse dangerous situations. Critics worry about mission creep, militarization, and the lack of clear rules for when armed or surveillance-equipped robots can be used in civilian neighborhoods. This weekly robotics news story highlights a key fault line: robots saving lives versus robots changing the feel of public policing.

Key details

- Over 60 bomb squads and SWAT teams reportedly use Spot NZ Herald

- Typical deployments: standoffs, hazardous scenes, hostage incidents

- Raises debates over oversight, accountability, and civil liberties

13. Why Every Robotics Lab Suddenly Has a Clothes-Folding Demo

Laundry as the benchmark test for manipulation AI | Weekly Robotics News | The Bolt and the Byte

Story

An IEEE Spectrum explainer points out that nearly every major manipulation lab and startup now shows robots folding towels, shirts, or napkins. IEEE Spectrum Companies like Figure, Weave Robotics, Physical Intelligence, and others use laundry as a benchmark because it’s hard enough to be interesting, but forgiving enough that small errors don’t shatter glass or break machinery.

Modern imitation-learning methods and diffusion-style policies can now learn from thousands of human demonstrations to produce smooth, dexterous folding motions. In this weekly robotics news segment, the takeaway is simple: if a robot can handle messy, deformable cloth, it’s probably ready for a lot of other real-world tasks.

Key details

- Clothes folding is now a go-to demo for manipulation startups IEEE Spectrum

- Powered by large datasets and imitation learning

- Serves as a stepping stone toward broader household skills

14. German Firm Launches Agile One, a Humanoid for Industrial Work

From cobots to full-body factory helpers | Weekly Robotics News | The Bolt and the Byte

Story

A German robotics company has unveiled Agile One, a full-size humanoid robot designed for warehouses and factories rather than sci-fi demos. The bipedal robot is built to walk around industrial sites, lift and carry loads, and operate in spaces originally designed for people, not conveyor belts. DC Velocity

Agile One is expected to work alongside traditional automation, taking on tasks that are too unstructured for fixed arms or simple mobile bases. In this weekly robotics news piece, Agile One represents a European answer to US and Chinese humanoids—a focus on practical, revenue-generating deployments in logistics and manufacturing.

Key details

- New humanoid robot aimed at logistics and industrial tasks DC Velocity

- Designed to navigate human-oriented spaces and handle payloads

- Part of a growing wave of “factory first” humanoid designs

15. Viam and Universal Robots Partner on AI-Powered Industrial Automation

Cobots plus cloud software for tough manufacturing jobs | Weekly Robotics News | The Bolt and the Byte

Story

Software platform Viam has announced a partnership with Universal Robots to deliver AI-powered automation systems for marine and industrial manufacturers. Using UR’s collaborative robot arms and Viam’s software, the companies have built a robotic block-sanding system for fiberglass boat hulls that can run for long shifts while maintaining consistent quality. The Robot Report+1

Viam says the same stack can be adapted for gelcoat and paint application, wood sanding, and polishing across furniture, construction, and other sectors. For this weekly robotics news roundup, the collaboration shows how “software-first” platforms are starting to ship complete, production-ready robot cells instead of just toolkits.

Key details

- Partnership between Viam and Universal Robots targets marine and manufacturing sectors Investing News Network (INN)

- First highlighted use case: robotic sanding of fiberglass hulls

- Viam’s platform is hardware-agnostic, designed to scale to many robot types

Q1. What is Weekly Robotics News and who is it for?

Weekly Robotics News is our curated digest of the most important robot and AI stories from around the world. It’s written for founders, engineers, investors, students, and anyone who wants a clear snapshot of where robotics is really heading without wading through dozens of random tech headlines.

Q2. How do you choose which stories appear in Weekly Robotics News?

We prioritize stories that show real progress: robots moving from demos into production, big funding rounds, policy changes, and new research with clear practical impact. If a piece of news helps you understand where robotics is going next, it has a good chance of landing in Weekly Robotics News.

Q3. Are these robots actually deployed, or are they just lab demos and viral videos?

It’s a mix. Some stories cover robots that are already deployed in factories, warehouses, hospitals, or city streets. Others focus on prototypes, research platforms, or early pilots. In each story we try to make it clear whether the robot is shipping, piloting, or still in the experimental stage so Weekly Robotics News stays honest about what’s real and what’s still hype.

Q4. How will humanoid and industrial robots affect jobs?

Many of the robots we cover are designed to take over repetitive, heavy, or dangerous tasks. That can improve safety and productivity, but it also reshapes certain jobs. Our goal in Weekly Robotics News is not to cheerlead automation blindly, but to track how work is changing—where robots are replacing tasks, where they’re creating new roles, and where human skills become even more valuable.

Q5. Why do you cover both tiny microrobots and big warehouse robots in the same issue?

Because the robotics ecosystem moves together. Advances in sensors, AI models, control theory, or new materials at one scale often show up later in other types of robots. Weekly Robotics News aims to give you a complete picture: from microrobots in the lab to humanoids on factory floors and mobile robots in public spaces.

Q6. How can I stay updated between Weekly Robotics News editions?

If you want more than one big Friday digest, you can follow our additional news editions during the week, keep an eye on our social channels, or subscribe to alerts. Weekly Robotics News is the flagship roundup, but the extra issues help you track fast-moving stories that can’t wait for the next Friday.

Conclusion

This edition of The Bolt and the Byte shows how quickly the robotics landscape is widening. On one side, we see humanoids and industrial systems moving into real workplaces—supporting warehouse staff, stepping onto factory floors, and even showing up in policing and public safety. On the other, research labs are pushing boundaries with microrobots, embodied AI models, and new control techniques that will shape the next generation of machines.

A common thread across this week’s stories is convergence: cloud-scale “brains” for fleets of robots, simulation tools that stress-test entire factories before hardware arrives, and AI models that connect language understanding with physical action. Whether those robots are walking on two legs, rolling on wheels, or swimming through fluids, they’re all drawing from the same accelerating stack of AI and hardware.

As always, the real impact won’t just be technical—it will be social and economic. How we decide to deploy these systems, regulate them, and share their benefits will matter just as much as the underlying breakthroughs. Until the next edition of The Bolt and the Byte, stay curious and keep watching how robots are quietly rewriting what we consider “normal” work.