Table of Contents

Introduction: The Evolution of a Humanoid

From Science Fiction to Factory Floor

What once belonged to the realm of science fiction is now standing upright, blinking its optical sensors, and taking its first confident steps into real factories.

The Tesla Optimus Gen 2 marks a genuine leap toward that long-imagined future of humanoid robotics. Announced by Elon Musk as part of Tesla’s mission to “build the world’s most advanced AI-powered machines,” the robot represents both an engineering milestone and a philosophical statement about the next chapter of human-machine collaboration.

In 2021, Tesla revealed its first prototype to skepticism and curiosity alike. Just two years later, Optimus Gen 2 has emerged sleeker, lighter, and 30 percent faster an early sign that Tesla is intent on making humanoid robots as scalable as its electric cars. It’s not just an R&D project; it’s a cornerstone of Tesla’s AI roadmap.

Elon Musk’s Vision: A Robot in Every Home

Elon Musk’s ambitions for Tesla have always extended beyond cars. He talks about a world where Tesla bots perform “unsafe, repetitive, or boring tasks” across factories, homes, and even healthcare.

In his vision, automation is not a threat to humanity but a multiplier of productivity a way to offload drudgery and unlock human creativity. The company’s massive advantage lies in data: billions of miles of driving information already training Tesla’s neural networks on perception, control, and decision-making. The same AI backbone powering self-driving cars now teaches robots to navigate a human world.

The Leap from Gen 1 to Gen 2

The first Optimus was mostly a proof of concept. It could walk, wave, and lift small loads, but its movements were stiff and tentative.

Optimus Gen 2, unveiled at the end of 2023, shows real maturity. Tesla redesigned nearly every actuator, trimmed 10 kilograms off the frame, and introduced 11 degrees of freedom in each hand. It moves with surprising fluidity, squats, balances on one leg, and delicately manipulates an egg without cracking it.

Behind these gestures lies a new generation of Tesla-designed actuators, tactile sensors, and an upgraded control system derived from the company’s Full Self-Driving (FSD) computer.

Under the Hood: A Look at Optimus Gen 2’s Specifications

Tesla describes Optimus Gen 2 as a “bi-pedal humanoid robot built for scalable production.”

Let’s unpack what that means mechanically, electronically, and computationally.

Physical Attributes: Height, Weight and Build

Standing 173 centimeters (5 ft 8 in) tall and weighing roughly 57 kilograms (125 lbs), the robot mirrors the proportions of an average human.

Its frame combines aluminum and lightweight composites for structural rigidity without bulk. Each joint houses a compact Tesla actuator designed in-house to provide smooth torque control.

It can carry up to 20 kilograms (44 lbs), enough for common industrial handling tasks or household chores.

Detailed Specifications Table

| Feature | Tesla Optimus Gen 2 | Boston Dynamics Atlas | Agility Robotics Digit |

|---|---|---|---|

| Primary Focus | Scalable, general-purpose robotics | Mobility, agility, research testbed | Logistics, warehouse tasks |

| Height | ~173 cm | ~150 cm | ~175 cm |

| Weight | ~57 kg | ~89 kg | ~65 kg |

| Payload Capacity | ~20 kg | ~11 kg | ~16 kg |

| Power Source | Electric | Electric / hydraulics hybrid | Electric |

| Degrees of Freedom | 28+ (11 per hand) | 28+ | 20–22 |

| Key Differentiator | AI, scalability, cost focus | Acrobatics, dynamic mobility | Bipedal stability in logistics |

The Power Within: Actuators, Sensors and Battery Life

Every joint of Tesla Optimus Gen 2 is powered by custom-built actuators, combining high torque with energy efficiency. These aren’t off-the-shelf servos; they’re precision-engineered to mimic human muscle dynamics.

Force-feedback sensors inside each joint monitor resistance in real time, allowing graceful movement and self-correction. The tactile sensors embedded in its fingertips deliver a delicate sense of touch vital for safe human interaction.

The robot draws energy from a dense lithium battery integrated into its torso, targeting a full day of continuous operation before recharge. Efficient thermal management keeps the powertrain cool, and regenerative braking recovers energy during motion.

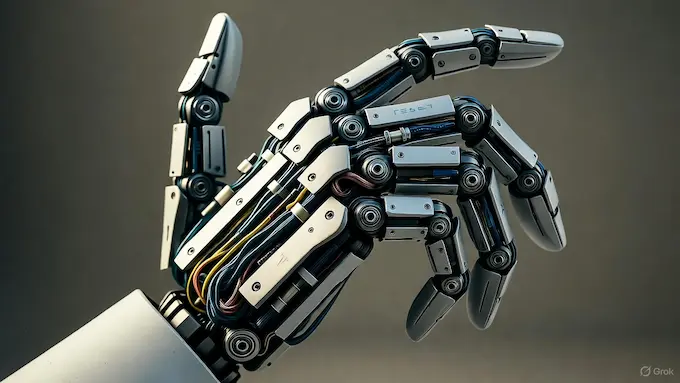

A Delicate Touch: Advanced Hand and Finger Dexterity

The new Tesla hand design is arguably the most impressive leap. Each hand offers 11 degrees of freedom, giving Optimus Gen 2 human-like finesse. It can thread a needle, pick up fragile objects, or handle tools with precision.

Tactile sensing and micro-motor control combine to produce a range of grips from a firm grasp on a wrench to the gentle lift of a strawberry.

The Brains of the Operation: AI and Neural Integration

Inside its chest beats the same silicon heart as Tesla’s self-driving cars: the FSD computer, running neural networks optimized on the Dojo supercomputer.

Vision from multiple cameras feeds into AI models trained on human movement and object recognition. The result is context-aware control: Optimus Gen 2 can interpret its surroundings, plan trajectories, and adapt to unexpected obstacles.

This AI system continuously learns from both simulation and real-world feedback. Over time, it refines gait, grip, and task sequences the same iterative process that transformed Tesla Autopilot into a market-leading driver-assist system.

Performance and Benchmarks: Putting Optimus to the Test

Walking the Walk: Speed, Agility and Balance

The first thing you notice when Tesla Optimus Gen 2 moves is how human it feels. Gone are the clunky shuffles of early prototypes. With 30 percent faster locomotion, improved joint control, and dynamic balancing, the robot walks with a natural rhythm each step a small dance between AI prediction and physical feedback.

Tesla engineers achieved this by pairing lightweight mechanics with advanced trajectory optimization. Gyroscopes and force sensors constantly calculate micro-adjustments, allowing the robot to recover from pushes or minor slips instantly.

In the Real World: Demonstrated Tasks and Capabilities

Tesla has already deployed Optimus Gen 2 in limited factory tests, sorting parts and assisting with simple assembly work. Videos show the robot lifting objects, placing components with steady precision, and navigating a busy industrial floor. Its vision system recognizes tools and components, while AI planning software assigns priority tasks.

Perhaps the most viral demo was Optimus handling an egg without breaking it proof of the robot’s fine motor skills. This test symbolizes Tesla’s goal: not just strength or speed, but trustworthy dexterity.

Learning on the Job: AI-Powered Skill Acquisition

What makes Optimus Gen 2 a true AI robot is its capacity to learn. Tesla’s neural network architecture allows the bot to observe human actions and replicate them. Through imitation learning and reinforcement loops, the robot improves with each iteration. This means a factory worker could demonstrate a task once, and the robot would repeat it reliably within minutes.

That capability turns Optimus Gen 2 from a fixed-function machine into a general-purpose assistant a core difference between traditional automation and the AI-driven humanoid future Tesla is building.

The Robotic Landscape: Optimus Gen 2 in Comparison

Tesla isn’t alone in this race. Boston Dynamics’ Atlas, Agility Robotics’ Digit, and Engineered Arts’ Ameca each represent different approaches to humanoid design. Where Tesla excels is in scalability and integration: combining AI, manufacturing capacity, and supply-chain muscle.

| Specification | Details |

|---|---|

| Height | 173 cm (5 ft 8 in) Sources: Brian D. Colwell, Wevolver, Robots Guide |

| Weight | 57 kg (125 lb) Sources: Brian D. Colwell, Not a Tesla App, Robots Guide |

| Payload Capacity | 20 kg (44 lb) Sources: Robots Guide, Wevolver |

| Walking Speed | ~0.6–0.8 m/s (≈ 30 % improvement) Sources: Robots Guide, Weights & Biases, blog.robozaps.com |

| Degrees of Freedom | ~28+ total, 11 in each hand Sources: Standard Bots, humanoid.guide, blog.robozaps.com |

| Actuators | Tesla-designed rotary/linear actuators integrated with custom electronics Sources: Robots Guide, Not a Tesla App, Hardware Acceleration in Robotics |

| Sensors | Vision (cameras), tactile fingertips, force/torque in joints/feet Sources: Brian D. Colwell, Not a Tesla App, blog.robozaps.com |

| Processing Unit | Tesla Bot Brain, shared lineage with FSD compute stack Sources: Brian D. Colwell, Hardware Acceleration in Robotics, Tesla |

| Battery | Undeclared; “all-day operational” goal (speculative) Sources: Built In, qviro.com |

| Materials | Lightweight composites, precision structural elements (unconfirmed) Sources: Built In, Robots Guide |

The Tesla Advantage: Scalability and Cost Efficiency

Boston Dynamics has stunning agility, but its robots remain lab curiosities with million-dollar price tags. Agility’s Digit is commercial, yet limited to logistics. Tesla’s edge is its ability to mass-produce complex hardware profitably. The company already builds millions of vehicles with robotic precision extending that expertise to Optimus Gen 2 is natural progression.

More importantly, Tesla controls the entire stack: AI training, actuator design, battery supply, and manufacturing automation. That vertical integration could cut costs dramatically, making Tesla Optimus Gen 2 the first humanoid robot priced for mass markets rather than research labs.

The Future is Now: Potential Applications and Societal Impact

Transforming Industries

In manufacturing and logistics, Tesla Optimus Gen 2 promises a seismic shift. Imagine Tesla factories where humanoids work side-by-side with machines sorting components, transporting materials, and handling hazardous tasks with zero fatigue. Automation of repetitive labor could free human workers for creative, technical, and supervisory roles.

Analysts estimate the commercial service robot market to reach $3.5 trillion within two decades. Tesla’s entry accelerates that trajectory by blending AI and economies of scale to deliver industrial-grade humanoids at consumer-level pricing.

- The Road Ahead: Challenges, Ethical Considerations, and Future Developments

- Robustness and fault recovery: hardware fails; software bugs slip in. The robot must be safe in failure modes.

- Energy and power constraints: balancing actuation, sensing, compute, communication battery limits bite hard.

- Perception in the wild: lighting, clutter, occlusion, adversarial environments a robot sees poorly under those.

- Safety and ethics: What if a robot’s update has a bug that causes harm? Who’s liable? Must satisfy regulatory and moral scrutiny.

- Labor market disruption: mass deployment might shift the job landscape in logistics, manufacturing, caregiving. We need policy, retraining, safety nets.

- Material supply & geopolitical dependencies: Rare earth elements, resilient supply chains matter. Tesla’s supply chain will be tested.

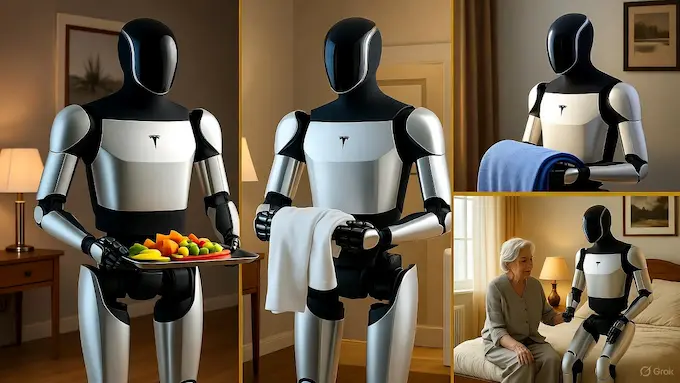

A Helping Hand at Home

While the factory floor is Tesla’s first target, the home is its ultimate frontier. Musk has spoken about a future where Optimus Gen 2 folds laundry, prepares meals, and assists the elderly. That’s still a technological stretch, but the robot’s AI and dexterity make it a plausible goal. Once costs drop and safety certifications mature, Tesla bots could become the domestic appliances of the AI age.

For a society aging rapidly and short on care workers, a capable humanoid assistant could be transformative. Yet ethical questions linger privacy, dependency, and the psychological impact of living with machines that mimic us.

Challenges and Ethical Frontiers

Robots that walk among us introduce complex questions. Who is responsible if a robot malfunctions and causes harm? How should societies retrain workers displaced by automation? And what happens when AI models begin making decisions faster than humans can audit them?

Tesla acknowledges these issues, emphasizing “safety at the hardware level.” Redundant sensors, automatic shutdown protocols, and restricted motion zones aim to make Optimus Gen 2 as safe as a washing machine though arguably a more imposing one.

Regulatory bodies will need new frameworks to certify humanoid robots, much as aviation does for aircraft. Tesla’s influence could help set those standards.

Conclusion: More Than Just a Machine

The Tesla Optimus Gen 2 embodies a fusion of mechanical engineering, artificial intelligence, and human ambition. It’s no longer a science-fair prototype but a commercial platform that could reshape labor, production, and daily life. If Tesla succeeds in mass-producing Optimus as it did its cars, the world will witness the first scalable hum

What is the Tesla Optimus Gen 2?

The Tesla Optimus Gen 2 is a next-generation humanoid robot designed by Tesla to perform repetitive, dangerous, and complex tasks in both industrial and domestic environments. It features Tesla’s in-house AI, self-balancing locomotion, and tactile sensing—making it capable of handling delicate objects, walking autonomously, and learning new tasks through neural network training.

How is Tesla Optimus Gen 2 different from its first generation?

Optimus Gen 2 introduces major upgrades over the original prototype, including a 30% faster walking speed, 10 kg weight reduction, and redesigned actuators. Its new hands provide 11 degrees of freedom for precise control, allowing it to perform fine motor tasks like picking up fragile objects. It’s also powered by Tesla’s Full Self-Driving (FSD) computer for smarter real-time decision-making.

What tasks can Tesla Optimus Gen 2 perform?

The Tesla Optimus Gen 2 humanoid robot can sort materials, handle assembly work, carry objects, assist with logistics, and even manipulate fragile items like eggs without breaking them. In the long term, Tesla plans for it to help with household chores, elderly assistance, and other service-oriented roles that require adaptability and safety.

How does Tesla Optimus Gen 2 learn and adapt?

Optimus Gen 2 uses Tesla’s AI architecture similar to what powers the company’s autonomous vehicles. Through imitation learning and reinforcement training, the robot observes human demonstrations and refines its behavior over time. Its neural networks continuously improve motion control, grip precision, and balance based on real-world feedback.

What are the specifications of Tesla Optimus Gen 2?

The Tesla Optimus Gen 2 stands 173 cm tall, weighs 57 kg, and carries up to 20 kg. It includes over 28 degrees of freedom, Tesla-designed actuators, tactile sensors in its fingertips, and an all-day integrated battery. The robot runs on Tesla’s FSD computer, giving it strong AI-based perception and real-time control capabilities.

When will Tesla Optimus Gen 2 be available to the public?

Tesla has not announced an official release date for Optimus Gen 2. The robot is currently in active development and internal testing within Tesla’s factories. Elon Musk has suggested that commercial availability could begin once production costs are reduced and safety standards for humanoid robots are finalized.