Table of Contents

Cargill Deploys Boston Dynamics’ “Spot” Robot Dog for Safer, Smarter Factories

ROBOTICS NEWS October 17 2025

Welcome to Robotics News October 17, 2025 your weekly AI robotics roundup covering breakthroughs from Tesla, Dexory, Figure AI, and beyond.

Lead:

Industrial automation isn’t just about efficiency anymore it’s about safety, foresight, and human-machine collaboration. Cargill’s Amsterdam plant is proving that point by deploying Spot, Boston Dynamics’ intelligent quadruped robot, to perform thousands of autonomous inspections every week.

Body:

Spot now operates as a full-time inspection specialist inside Cargill’s Multiseed crush and refinery facility, where it roams factory floors, monitors heat signatures, listens for anomalies, and visually scans for leaks or obstructions. With its onboard AI and advanced sensors, the robot collects thermal, acoustic, and visual data in real time enabling predictive maintenance long before humans can detect a fault. During trials, Spot identified overheating bearings and a decanter operating above safe limits, helping engineers avoid costly downtime. Beyond inspection, Spot also flags misplaced tools, open doors, or blocked walkways becoming an essential player in Cargill’s safety ecosystem.

The project has turned into a model of workforce synergy: operators are being trained to design Spot’s routes, interpret inspection data, and refine operational AI patterns. According to Cargill, this is only the start plans are already underway to roll out similar robotic systems across other European sites. It’s not just about replacing labor, but creating a data-rich environment where human expertise is enhanced by robotic precision.

Hong Kong Introduces Dual-Arm and Quadruped Robots to Power Smart Cities

Lead:

Hong Kong’s next generation of robotics research is blurring the lines between academic innovation and commercial impact. Two locally developed AI-powered robots one with four legs, the other with twin arms are poised to transform logistics, automation, and retail across the region.

Body:

The Hong Kong Centre for Logistics Robotics (HKCLR) at The Chinese University of Hong Kong unveiled LY1, a quadruped robot agile enough to traverse stairs, rubble, and narrow corridors, and a dual-arm system capable of manipulating objects with human-like dexterity. Both systems are driven by vision-language models that enable them to perceive their surroundings, interpret spoken commands, and react to real-world conditions without direct programming. This allows the robots to restock shelves, sort parcels, or assist workers in industrial environments a step toward fully collaborative logistics.

What makes this launch particularly significant is that both robots were designed entirely in Hong Kong, aligning with the government’s push for local AI manufacturing. Officials praised the effort as a showcase of how government, academia, and industry can co-create a competitive robotics ecosystem. With China doubling down on autonomous technologies and logistics innovation, these systems could soon form part of the smart city infrastructure across Asia.

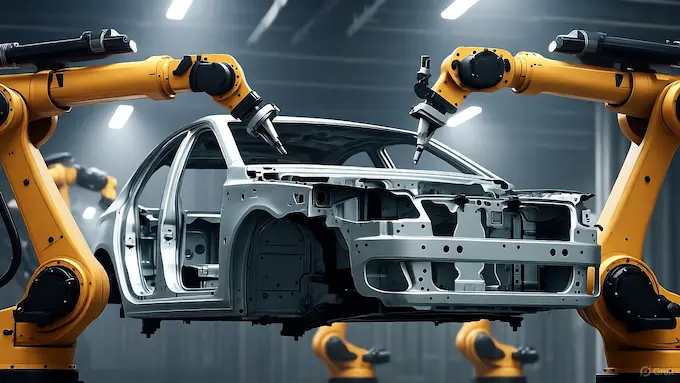

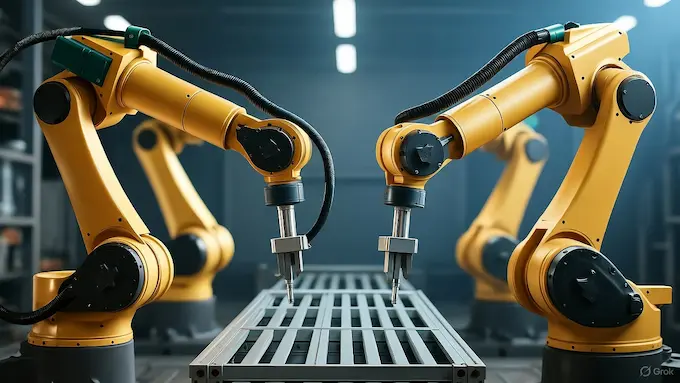

Google DeepMind’s RoboBallet Teaches Industrial Robots to Move in Seconds

Lead:

For years, programming industrial robots to perform coordinated movements has been an engineering headache until now. Google DeepMind’s new RoboBallet AI can choreograph multiple robots in complex environments within seconds, a leap forward that could redefine manufacturing efficiency.

Body:

The RoboBallet system eliminates the need for hours of manual programming by using graph neural networks an advanced AI framework that learns spatial relationships between robots, tools, and obstacles. In testing, it successfully planned movement trajectories for up to eight robotic arms performing 40 different tasks simultaneously, all while preventing collisions and optimizing speed. By converting entire factory setups into graph data, DeepMind’s system allows robots to share real-time awareness, improving precision and cooperation between units.

Unlike traditional methods that rely on static pre-programmed paths, RoboBallet adapts dynamically, recalculating new motion plans when an object shifts or another robot moves unexpectedly. Its name reflects its elegance robots working together in harmony, like dancers following a shared rhythm. According to DeepMind engineer Matthew Lai, this opens the door for real-time design simulations, where engineers can test configurations or add robots virtually before implementation. The implications are vast from automotive assembly to semiconductor fabrication making it one of the most practical AI applications for manufacturing yet.

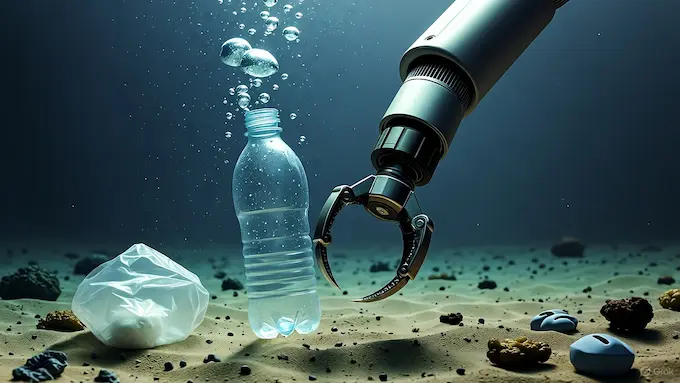

Germany’s Diving Robot Takes on Ocean Trash with AI Precision

Lead:

As oceans choke under billions of tons of submerged waste, engineers in Germany have unveiled a bold solution an autonomous diving robot that can spot, classify, and retrieve underwater debris with near-human accuracy.

Body:

Developed by the Technical University of Munich (TUM) under the SEACLEAR 2.0 project, this AI-powered robot combines sonar mapping, neural networks, and high-resolution imaging to detect sunken litter. Its gripper applies up to 4,000 newtons of force to pull heavy items like nets, tires, and metal scraps from the seabed. Trained on 7,000 labeled images, it transforms 2D detections into 3D models for real-time manipulation.

During field trials in Marseille, the 265 lb. machine worked with an autonomous service boat to retrieve waste while tethered to a surface vessel for constant data flow and power. The robot’s neutral buoyancy and eight mini-turbines allow delicate maneuvering even in low-visibility conditions. TUM scientists envision fleets of such divers patrolling coastal regions, cutting human risk in polluted waters while supporting a global push for sustainable cleanup.

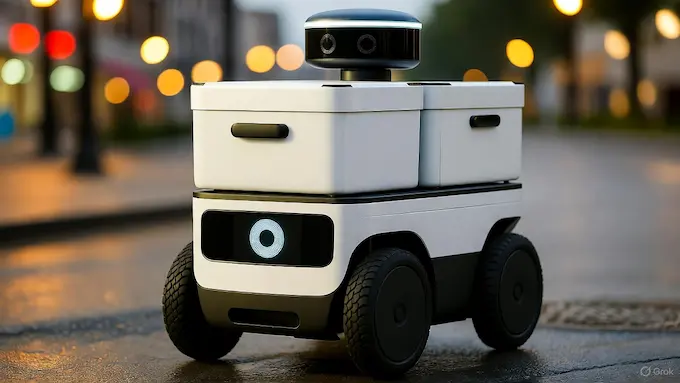

Serve Robotics’ Gen3 Delivery Bot Tops Fast Company’s “Next Big Things”

Lead:

Autonomous delivery has moved from novelty to necessity and Serve Robotics is leading the charge. The San Francisco startup’s third-generation delivery robot just claimed the top robotics award in Fast Company’s Next Big Things in Tech 2025 list.

Body:

Serve’s Gen3 unit represents the latest evolution in last-mile automation: faster speeds, longer ranges, and smarter obstacle avoidance through advanced perception AI. Each robot can carry multiple deliveries while navigating sidewalks and crosswalks independently. Since late 2024, over 1,000 Gen3 units have hit streets in major U.S. cities under partnerships with DoorDash and Uber Eats, making Serve the largest active autonomous delivery fleet in North America.

CEO Ali Kashani describes the recognition as validation of years of research aimed at safer, zero-emission logistics. The company plans to double deployments by 2025, leveraging a modular design that simplifies scaling. Analysts say Serve’s data-driven fleet could cut urban delivery emissions dramatically while reducing labor strain. With every trip logged to the cloud, these robots are becoming part of the urban digital fabric a preview of tomorrow’s self-managing logistics networks.

Dexory Raises $165 Million to Build the ‘Digital Twin Warehouse’

Lead:

UK robotics firm Dexory has closed a $165 million round to supercharge its vision of intelligent, self-learning warehouses where autonomous towers map every pallet, aisle, and barcode in real time.

Body:

Dexory’s 46-foot-tall scanning robots, equipped with LiDAR, RFID, and optical sensors, patrol warehouses to create 3D digital twins via its DexoryView platform. The system synchronizes with existing warehouse-management software, replacing manual audits with constant, high-fidelity inventory data. Logistics titans like DHL, Maersk, and GE Appliances already use the platform to improve accuracy and safety.

The company’s $100 million Series C round, led by LTS Growth and Endeavor Catalyst, plus a $65 million debt facility, will expand its presence in North America and Asia-Pacific. CEO Andrei Danescu says Dexory’s modular AI allows warehouses to evolve gradually, integrating with legacy systems while training algorithms on live operations. By turning physical inventory into data streams, Dexory aims to eliminate lost stock, cut downtime, and make global supply chains adaptive and self-correcting.

Tensor Auto Reveals the World’s First Personal Robot Car

Lead:

Imagine a car that drives, parks, and charges itself and even learns your daily routine. At GITEX Global 2025, U.S. firm Tensor Auto unveiled the Tensor Robocar, the world’s first fully autonomous personal robot vehicle.

Body:

Built from scratch as a Level-4 autonomous machine, the Tensor Robocar eliminates the need for a driver’s license or special insurance. It uses five LiDAR modules and 100 sensors to build a 360° awareness map, supported by 8,000 processing units that analyze environmental data in real time.

Unlike retrofit self-driving cars, Tensor’s design integrates autonomy at the hardware core. It can drop children at school, navigate urban roads, and dock itself for wireless charging all via voice command. Its AI learns user behavior, remembering common routes and preferred times, while all data remains fully encrypted. Company officials say the car’s arrival marks a shift toward “personalized autonomous mobility,” where vehicles behave like intelligent assistants rather than transport tools.

Wayve and Nvidia Eye $2 Billion Funding to Accelerate Autonomous AI

Lead:

British autonomous-driving startup Wayve is preparing a potential $2 billion funding round, with Nvidia reportedly considering a $500 million strategic investment a move that could redefine Europe’s role in global autonomous tech.

Body:

Wayve’s partnership with Nvidia dates to 2018, and its next-generation Gen-3 platform will run on Nvidia Drive AGX Thor, powered by the Blackwell GPU architecture. Together, they aim to deliver embodied AI that allows vehicles to learn from experience rather than rely solely on coded rules.

The investment would boost production of Wayve’s “AI Driver,” which targets Level 3–4 autonomy across city and highway domains. Analysts believe this alliance could position Wayve as a European counterweight to Tesla and Cruise. CEO Alex Kendall says the collaboration will “bring safe, scalable autonomous mobility to market worldwide.” Investors view it as proof that high-impact AI ventures are thriving outside the U.S., with cross-border funding from Asia and the Middle East signaling global momentum.

Unitree’s G1 Robot Shows Gymnastic Skills and Hints at a Bigger Purpose

Lead:

Chinese robotics firm Unitree has stunned audiences again with a video of its humanoid G1 robot performing flips, spins, and kung-fu sequences — but the real question is what this agility means for the future of robotics.

Body:

Standing 130 cm tall, the G1 uses advanced reinforcement-learning algorithms and lightweight actuators to perform dynamic movements with unprecedented balance. The demonstration, which went viral online, sparked both awe and skepticism. While some saw a technological marvel, others questioned its practicality beyond performance.

Unitree says the G1 isn’t just for show it’s a platform for AI development, research, and industrial testing. The robot’s real-time decision-making allows it to navigate unknown environments and adapt its gait on the fly. Offered at $21,600, Unitree markets G1 to universities, developers, and automation labs seeking an affordable testbed for humanoid AI. The company believes its technology could soon move from gym floors to warehouses and rescue operations, bridging the gap between research and industry.

Flexxbotics Raises $15 Million to Bring AI Coordination to Factory Robots

Lead:

Boston-based startup Flexxbotics has raised $15 million in Series A funding to solve one of manufacturing’s biggest headaches getting industrial robots from different brands to collaborate intelligently.

Body:

Flexxbotics’ cloud-based Robot Orchestration Platform allows robotic arms, CNC machines, and inspection stations to communicate seamlessly regardless of their manufacturer. The system interprets commands, translates them into each robot’s native language, and optimizes task scheduling on the fly. This interoperability layer effectively gives robots a “common brain,” enabling full coordination across mixed-production lines.

The funding round, led by True Ventures with participation from Grit Ventures and Hyperplane, will accelerate the company’s expansion in North America and Europe. Flexxbotics claims its customers report up to 30% faster production times after integration. The platform also includes predictive analytics, letting operators see when a robot’s workload or tool path needs recalibration. By bridging the gap between industrial IoT and robotics, Flexxbotics is positioning itself as the digital nervous system of smart factories.

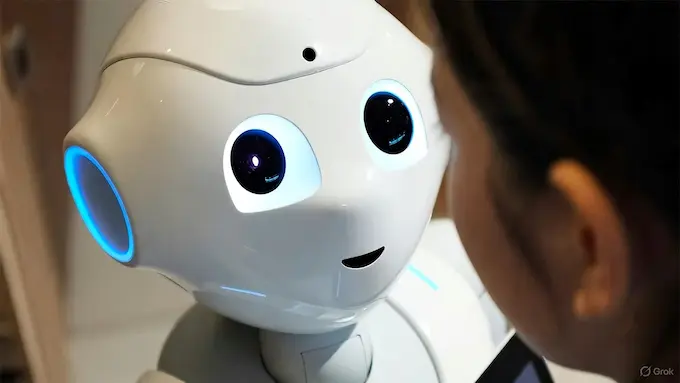

Mirror Me’s ‘Baobao’ Robot Redefines Emotional AI in Consumer Tech

ROBOTICS NEWS October 17 2025

Lead:

Chinese robotics company Mirror Me has unveiled Baobao, a humanoid companion robot designed not just to assist but to understand. The robot blends AI perception, emotional responsiveness, and sleek design to reshape the personal robotics market.

Body:

At just under a meter tall, Baobao features a dynamic facial display capable of conveying emotions through expressive animations. Its gesture-recognition interface reduces sensor noise, allowing precise motion capture and natural human interaction. Baobao’s speech model recognizes tone and sentiment, adapting its responses to user mood whether in a family setting, retail, or educational use.

Company founder Wang Zhi describes Baobao as “a bridge between technology and daily life.” The robot can play music, answer queries, and even guide customers in stores using conversational AI. Analysts see Mirror Me’s debut as China’s push into emotionally aware robotics a market expected to exceed $10 billion by 2027. Baobao’s emotional intelligence may become a blueprint for how machines coexist gracefully with people in everyday environments.

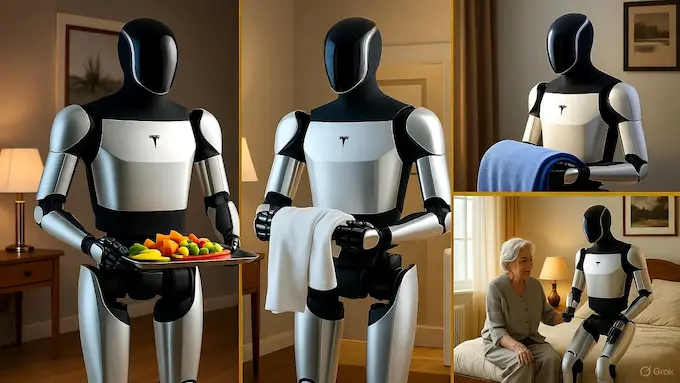

Tesla Reportedly Orders $685 Million in Parts for Optimus V3 Humanoid Robot

Lead:

Tesla may have quietly moved its humanoid project into mass-production mode. Reports from China suggest the company placed a $685 million order for actuators the mechanical “muscles” that power its Optimus V3 robot.

Body:

According to Sina News, Tesla’s supplier Sanhua Intelligent Controls received a massive order for linear actuators, fueling speculation that Optimus V3’s design has been finalized and manufacturing could begin in early 2026. Analysts estimate the component volume could support production of up to 180,000 robots far exceeding prototype scale.

While Tesla China declined to comment, industry sources say the company has solved early mechanical issues in the robot’s hands and joints. The Optimus project, first revealed by Elon Musk in 2022, aims to build a humanoid workforce for repetitive or hazardous factory tasks. Its integration with Tesla’s Dojo AI supercomputer gives it real-time learning and motion adaptation. The move signals that Tesla is transitioning from demonstration to deployment potentially positioning Optimus as the first commercially scaled humanoid platform in history.

Dobot’s MG400 and Nova Series Aim to Democratize Industrial Robotics

Lead:

Chinese manufacturer Dobot Robotics is breaking barriers in accessibility by bringing industrial-grade robotic arms to small businesses and classrooms worldwide.

Body:

The company’s latest MG400 and Nova series feature compact 4-axis designs that fit on a desktop yet perform tasks such as welding, pick-and-place, and quality inspection with professional accuracy. Using an intuitive drag-and-teach interface, users can train these robots without coding, lowering the entry barrier for automation.

The Nova series, styled in multiple colors, targets retail and customer-service applications, while the MG400 focuses on education and light manufacturing. Dobot’s CEO Jerry Liu says the goal is to make robotics as familiar as personal computers once were: “Every small enterprise deserves automation.” With distributors in over 80 countries, Dobot’s products are bridging the gap between hobby robotics and enterprise automation, empowering the next generation of robotic innovators.

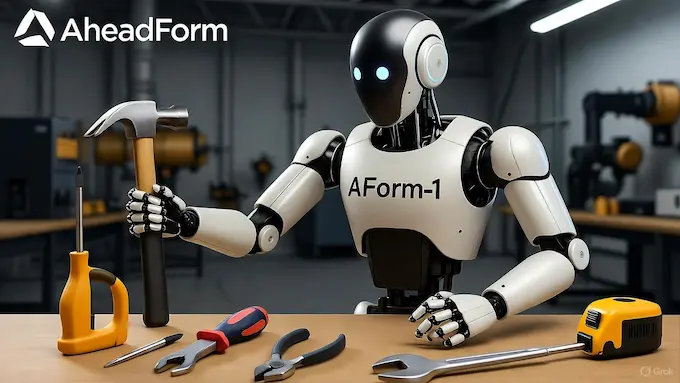

AheadForm’s Humanoid Research Project Pushes Cognitive AI Boundaries

Lead:

Singapore-based AheadForm Robotics is exploring how humanoid robots can reason and adapt through multimodal cognition a leap toward machines that truly “understand” their environment.

Body:

The company’s Cognitive Motion Framework integrates computer vision, symbolic reasoning, and self-learning feedback loops to enable real-time problem-solving. Instead of relying solely on trained patterns, AheadForm’s prototype adapts dynamically to changes like identifying a missing tool and retrieving a replacement autonomously.

Its humanoid research platform, AForm-1, stands 165 cm tall and features over 30 degrees of freedom, allowing smooth, human-like gestures. The startup’s engineers describe it as an “embodied AI lab on legs,” built to explore how robots could one day think contextually. This kind of general-purpose learning framework could serve as a foundation for universal task robots, much like how large language models transformed text-based AI.

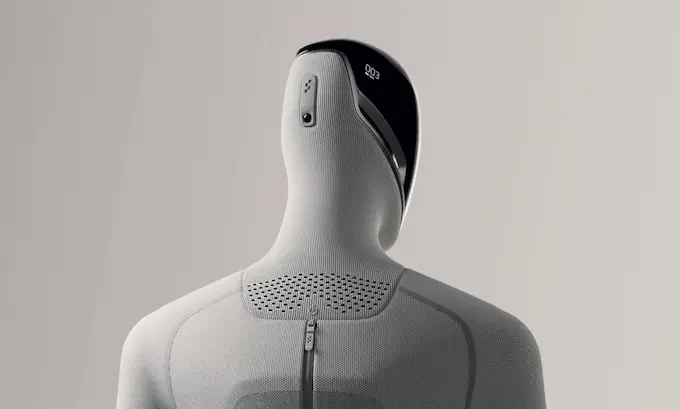

Figure 03 Humanoid Robot Set for Real-World Testing in 2026

Lead:

After months of teaser clips, California-based Figure AI has confirmed that its Figure 03 humanoid robot is entering field trials with major corporate partners in 2026 one step closer to commercial deployment.

Body:

Figure 03 builds upon the company’s prior models with stronger actuators, a lighter frame, and an upgraded brain powered by OpenAI’s multimodal GPT-5 system. The robot can perceive human speech, gestures, and visual cues simultaneously, enabling fluid workplace collaboration.

CEO Brett Adcock revealed that Figure 03 units will begin testing at logistics and retail sites next year, working alongside human staff to manage loading, sorting, and customer assistance. The company aims to validate how general-purpose humanoids perform under real economic conditions endurance, reliability, and perception in dynamic settings. Investors are betting big: the firm’s valuation recently topped $3.2 billion after a fresh funding round. Figure AI’s mission is clear bring human-level utility to machines without losing the safety and empathy that keep robotics beneficial to society.

About “The Bolt and The Byte”: A weekly robotics intelligence report by RoboticsNewsAI, exploring breakthroughs, investments, and the societal impact of intelligent machines.

As we close this week’s edition of Robotics News October 17, 2025 – The Bolt and the Byte, one theme stands out: intelligent machines are no longer distant experiments but active participants in industry, research, and society. From Tesla’s Optimus V3 and Figure 03 humanoid trials to Dexory’s warehouse AI and Cargill’s Boston Dynamics Spot, robotics continues to evolve from innovation to real-world integration. Stay tuned each Friday for the latest in AI-driven automation, humanoid development, and the ever-expanding frontier of robotics technology.

FAQs – Robotics News October 17, 2025

Q1. What are the biggest robotics highlights from October 11–17, 2025?

A1. Major developments include Tesla’s Optimus V3 humanoid moving toward mass production, Figure 03 entering field trials, Dexory raising $165 million to digitize warehouses, and Cargill’s Boston Dynamics Spot robot improving factory safety standards.

Q2. Why is Robotics News published every Friday?

A2. The weekly format allows readers to follow robotics and AI trends in real time. Each Friday edition like Robotics News October 17, 2025 – The Bolt and the Byte—summarizes the week’s most important breakthroughs, funding rounds, and social impacts of automation.

Q3. How is Tesla’s Optimus V3 different from earlier humanoid versions?

A3. The Optimus V3 features upgraded actuators, refined hand articulation, and tighter integration with Tesla’s Dojo AI system. These advances move the robot closer to real-world factory deployment.

Q4. What is Dexory’s $165 million funding round expected to achieve?

A4. The investment will expand Dexory’s AI-driven warehouse scanning platform, enabling global logistics firms to build accurate 3D digital twins of their facilities and improve real-time inventory accuracy.

Q5. Where can readers find previous editions of Robotics News?

A5. All weekly issues are archived at https://roboticsnewsai.com/weekly-robotics-news/ — a hub for every edition of The Bolt and the Byte published since 2025.

Reported by Arqam Aslam for RoboticsNewsAI.

Arqam covers humanoid robotics, AI-driven automation, and real-world deployment of intelligent machines. He tracks how robots are moving from demo videos to actual work in factories, hospitals, logistics, logistics centers, and retail.

Send tips, product announcements, demo footage, or correction requests to: tips@roboticsnewsai.com