Table of Contents

Introduction

In Weekly News Roundup ROBOTICS NEWS October 03, 2025 The world of robotics and artificial intelligence (AI) continues to move at breakneck speed. From humanoid robots entering shops and factories, to AI-powered machines building homes on Earth and preparing for the Moon, this week’s stories show how robotics is reshaping industry, construction, governance, and even politics. Let’s dive into the top 15 robotics and AI news updates you need to know this week.

1. A Robot That Saves Lives: ROMATRIS Revolutionizes Disaster Response

- Purpose: AI-assisted transport for disaster zones (rubble/rough terrain).

- Payload: 120 kg in official materials; some press report 150 kg ≈ 330 lb.

- Control: follow-me, waypoint navigation, gesture recognition; maps surroundings.

- Use-case: move generators, pumps, hoses, med kits where vehicles can’t reach.

- Status: DFKI + THW project; field exercises reported in 2025.

- DFKI — ROMATRIS project overview

- THW Security Research — ROMATRIS (English)

- Electronics360 — coverage citing ~330 lb payload

- Interesting Engineering — coverage citing ~330 lb payload

ROMATRIS — Key Specs

| Payload | 120 kg (official); some press report 150 kg ≈ 330 lb |

| Control | Follow-me, waypoint navigation, gesture recognition |

| Terrain | Rubble, uneven ground; maps surroundings |

| Use-case | Transport generators, pumps, hoses, medical kits |

Timeline

- Project phase (DFKI + THW): development and field exercises.

- 2025 updates: public demos/hand-off reported; several outlets cite 330 lb payload.

Video credit: DFKI/THW (embedded from YouTube).

Sources

Related: Disaster-response robots · DFKI · THW · Weekly Robotics News

Among the top robotics headlines this October is the story of ROMATRIS A Robot That Saves Lives When disaster strikes, every second counts, but often, human rescuers face treacherous terrain, collapsed buildings, and dangerous conditions that make it nearly impossible to reach victims in time. Now, a team of German researchers has unveiled a powerful ally for first responders: ROMATRIS, an AI-powered robot capable of hauling 330 pounds of life-saving equipment across rubble, ruins, and disaster zones.

Developed under a collaboration between the German Research Center for Artificial Intelligence (DFKI) and the Federal Agency for Technical Relief (THW), this rugged, semi-autonomous machine represents a major leap forward in how robotics can directly support emergency workers in the field. More than just a machine on wheels, ROMATRIS embodies a future where technology and human courage unite to save lives.

From Lab to Life-Saving Fieldwork

The ROMATRIS project (short for Robotic Material Transport in Disaster Situations) was born out of a simple but urgent problem: how do you get heavy, bulky equipment into places no truck, stretcher, or human can easily reach?

Traditional disaster response often requires volunteers to carry pumps, generators, hoses, and other gear by hand through debris fields, muddy terrain, or unstable ground. Not only does this slow down operations, but it also exposes emergency workers to unnecessary risks.

ROMATRIS changes the equation. Built to carry loads of up to 150 kilograms (330 lbs), the robot can shuttle life-saving equipment directly into danger zones, drastically cutting the physical burden on human teams.

Gesture Recognition Meets Artificial Intelligence

What makes ROMATRIS stand out isn’t just its brute strength it’s the intelligence behind it. The robot comes with multiple operating modes:

- Manual Remote Control – for direct handling.

- Follow-Me Mode – where it uses gesture recognition and person-tracking to shadow its human orator.

- Autonomous Shuttle Mode – allowing it to travel between two designated points without constant oversight.

This versatility means ROMATRIS can be deployed flexibly depending on the situation. At the heart of the system lies a depth camera paired with neural networks that translate simple human gestures into commands. An operator doesn’t need to be a robotics expert a simple wave or hand signal can send ROMATRIS moving forward, stopping, or adjusting its path.

Additionally, the robot integrates a 3D sensor array, ultrasonic detection, and laser systems for obstacle avoidance. Whether it’s navigating collapsed concrete, flooded streets, or dense forest trails, ROMATRIS creates a live map of its environment and moves with precision.

Human Testing, Human Impact

A Glimpse Into the Future of Crisis Logistics

The promise of ROMATRIS extends beyond Germany. As climate change intensifies natural disasters and urban populations grow, the need for agile, intelligent disaster-response tools is greater than ever. From earthquake-prone regions to flood hit cities, robots like ROMATRIS could become standard partners for emergency personnel worldwide.

DFKI project lead Martin Mallwitz noted: “With ROMATRIS, we are demonstrating how AI-supported robotics can support the work of emergency services.”

Looking ahead, future versions of the robot may carry medical supplies, deploy drones, or even help evacuate survivors in extreme scenarios. In other words, ROMATRIS is not just a transporter it’s the first step toward a new generation of robotic teammates in disaster relief.

The Bottom Line

Technology is often criticized for being too abstract, too focused on convenience or consumer gadgets. But ROMATRIS proves that when innovation is rooted in human need, it can quite literally save lives. By combining artificial intelligence, robust engineering, and a human-centered design process, this German-made robot points toward a future where machines don’t replace rescuers — they protect them.

2. Charlotte the Spider-Bot: Printing Homes on Earth and One Day, the Moon

The world faces two construction challenges at once: a global housing crisis and the daunting task of building human habitats on the Moon. Traditional methods struggle to keep up with Earth’s growing demand for affordable homes, while in space, transporting heavy building equipment is impractical. Enter Charlotte, a six-legged, spider-like robot designed to change how and where we build.

Developed by Crest Robotics and Earthbuilt Technology in Australia, Charlotte is no ordinary construction machine. This fully autonomous hexapod can 3D-print a 200-square-metre house in just 24 hours, using sustainable materials sourced locally. On Earth, that means low-cost, low-carbon housing. On the Moon, it could mean the difference between survival and stagnation for astronauts.

From Housing Crisis to Robotic Construction

Across the globe, rising construction costs and sluggish building timelines have left millions without adequate housing. Charlotte’s mission is to reverse this trend by providing rapid, scalable, and affordable building solutions.

Instead of relying on prefabricated parts or expensive concrete, Charlotte employs Earthbuilt Technology’s extrusion and compaction system. Attached to its undercarriage, this system collects materials like sand, soil, and even waste products such as crushed bricks. These are packed into long fabric tubes, layered, and compacted a process similar to the sustainable building technique known as Earthbagging.

The result durable, eco-friendly walls built at remarkable speed, with minimal reliance on costly supply chains.

The Spider Design Advantage

Unlike massive gantry-based 3D printers, Charlotte’s hexapod design is lightweight, foldable, and highly mobile. Its six legs provide stability across uneven ground, while its compact frame makes it easy to transport.

This engineering choice is not just convenient it’s essential for space exploration. Every kilogram on a rocket launch costs money and space. A construction robot must be portable, adaptable, and efficient. Charlotte checks all three boxes.

Building for the Moon

NASA and other space agencies plan to establish a sustainable human presence on the Moon within the next decade. That will require permanent shelters, landing pads, and even roads infrastructure impossible to haul from Earth A major theme in robotics for October 2025 seems to be Charlotte which is game changer in construction.

Charlotte could provide the solution. Once deployed on the lunar surface, it would use regolith (lunar soil) as building material, layering it into domes and shelters capable of shielding astronauts from radiation, extreme temperatures, and meteorite impacts.

Crest Robotics emphasizes that Charlotte’s lightweight frame makes it ideal for space missions: compact during transport, but powerful enough to carry out large-scale lunar construction autonomously.

The Global Race for Off-World Construction

Charlotte is not alone in the race. U.S. startup ICON is working with NASA on Project Olympus, developing systems to 3D-print lunar infrastructure. ICON has already built Mars Dune Alpha, a simulated habitat used for NASA’s Mars training missions.

But Charlotte’s unique spider-like form gives it an edge. Where large gantry printers struggle with portability, Charlotte can adapt to rough lunar terrain with ease, making it one of the most promising candidates for off-world building robots.

A Dual Purpose: Earth and Beyond

While space headlines grab attention, Charlotte’s immediate impact could be felt right here on Earth. By drastically cutting both the time and cost of homebuilding, Charlotte could become a key tool for tackling housing shortages in cities worldwide.

Imagine disaster-relief teams deploying Charlotte to rebuild homes after earthquakes, floods, or hurricanes. Instead of waiting months, survivors could have safe, durable shelters within days.

The Bigger Picture

Charlotte embodies a growing truth in robotics: the best innovations solve both humanitarian needs on Earth and exploration challenges in space. Just as the Roomba brought robotics into homes and Mars rovers brought them to other planets, Charlotte could soon be known as the robot that built homes across two worlds.

As Crest Robotics and Earthbuilt Technology refine its design, Charlotte is not just another construction robot it’s a pioneer. A spider-bot spinning the foundations of our future, brick by brick, both under our feet and above our heads.

3. A Store With No Humans: China’s First Robot-Run Bodega

What if the friendly shopkeeper at your corner store wasn’t human at all, but a humanoid robot? That’s not science fiction anymore it’s reality in Beijing, where a fully autonomous robot-run kiosk has just opened its doors. The project, launched by Chinese robotics firm Galbot, marks one of the boldest steps yet in merging humanoid robots with everyday life.

At the center of the experiment is the Galbot G-1, a dual-armed humanoid robot that can greet customers, hand out goods, and manage a store without human assistance it is the latest humanoid robotics developments this month show that our third story in robotics news October 03 edition will gain popularity and will become helpful in coordinating with robots in action . For now, it’s part novelty and part pilot program. But its presence has already drawn large crowds eager to see a robot shopkeeper in action.

From Humanoid Demos to Daily Service

Humanoid robots have long captured public imagination, from science fiction movies to flashy tech demos. But in real-world retail, machines have mostly been confined to vending machines, kiosks, and delivery bots. The Galbot G-1 aims to go a step further: offering a humanoid “store clerk” experience that feels more interactive.

Inside the kiosk dubbed Robodega customers can order snacks, drinks, and even pharmaceuticals, and the robot handles the entire transaction. No hidden operators, no human staff in the back. Galbot insists the store is fully autonomous, powered by its proprietary AI systems GroceryVLA and GraspVLA, which enable the robot to understand customer requests and manipulate objects with its robotic hands.

The Public Reaction: A Curious Spectacle

On opening day, videos of the G-1 serving customers quickly went viral on Chinese social media. Curious shoppers lined up not just to buy something, but to see the robot in action bending down to retrieve items, handing them over carefully, and acknowledging customers with simple gestures.

For many, the novelty outweighed the efficiency. The G-1 moves more slowly than a human clerk, and skeptics point out that a smart vending machine could deliver the same products in less time. But the human-like interaction gave the experience a unique edge. As one visitor described, “It’s not about how fast it is it’s about the feeling of being served by a robot.”

The Road Ahead: Scaling the Robodega

Galbot is not treating this as a one-off stunt. The company has already opened a second kiosk at Beijing’s Summer Palace, a major tourist site, and plans to roll out 100 robot-run stores across 10 Chinese cities within the next year.

For CEO Wen Airong, the challenges ahead are less about hardware and more about AI-human interaction. Two hurdles remain critical:

- Voice Interaction – Robots must handle different dialects, accents, and noisy environments to truly replace human clerks.

- Speed & Efficiency – To move beyond novelty, humanoid robots must become as quick and reliable as their human counterparts.

These are no small tasks. Navigating real-world social and linguistic complexity is something even advanced AI still struggles with.

A Glimpse of the Future?

Despite the limitations, Galbot’s Robodega offers a glimpse into how humanoids might enter everyday society. Instead of only serving in factories or research labs, humanoid robots could one day manage small retail stores, cafes, and service kiosks.

While efficiency may lag behind other forms of automation, the human-like form gives robots a role in customer-facing experiences, where interaction matters as much as speed.

Why It Matters

The Robodega experiment raises a key question: Do we want robots that merely deliver products, or robots that also deliver an experience?

Galbot believes the future lies in humanoids that blend convenience with familiarity. Whether customers come for a drink or just to watch a robot shopkeeper at work, Beijing’s robot-run store represents a small but symbolic shift in how humans and robots may soon share public spaces.

4.Smarter Than Maps: Robots Learn Navigation by “Forgetting” Like Humans

Robots are getting better at finding their way through chaotic environments and they’re doing it by copying how humans think. A research team at DGIST in South Korea has unveiled a breakthrough in “Physical AI” navigation, showing that when robots learn to spread and forget information like people do, they move more efficiently.

In tests simulating a warehouse filled with forklifts, crates, and shifting obstacles, robots equipped with the new system completed tasks 30% faster and boosted overall productivity by nearly 20%.

Why Forgetting Helps Robots Move Better

Traditional robots rely on rigid maps and react only to immediate changes. The result? Inefficient detours, repeated slowdowns, and even gridlock when operating in swarms.

Professor Kyung-Joon Park, who led the study, explained the inspiration: “In society, some news spreads fast but fades quickly. We modeled this process mathematically for robots.” By allowing machines to ignore outdated information and share only relevant updates, teams of robots could coordinate more naturally.

From Warehouses to Cities

The best part? This new navigation system doesn’t require expensive sensors. It works with basic 2D LiDAR and can be plugged directly into existing ROS 2 navigation stacks.

That means the upgrade could roll out quickly across logistics hubs, smart factories, drone fleets, and even self-driving cars. In the future, “forgetful” robots may also manage traffic flow in smart cities avoiding the kind of jams humans know all too well.

5. A Soft Robot That Walks, Swims, and Delivers Cargo

In nature, ants and water beetles move seamlessly between land and water. Inspired by this, researchers in China have built a tiny amphibious robot that can haul cargo across both environments, powered by three different environmental triggers: temperature, humidity, and magnetic fields.

Weighing just 8 milligrams, the soft robot may look delicate, but it can carry loads more than twice its own weight while navigating rugged terrain.

Triple Responsiveness: The Science Behind It

The team combined three smart materials into a layered “artificial muscle”:

- Polyamic acid film that expands and contracts with heat and humidity.

- Silicone rubber embedded with magnetic particles for precise remote control.

- A polyimide base for flexibility and durability.

This unique design prevents the interference issues that have plagued previous multi-stimulus robots, enabling smooth transitions from underwater swimming to land crawling.

Cargo Missions and Rescue Potential

In one demo, the robot picked up a tiny pebble, swam across water, climbed onto dry land, and delivered it to a target zone all autonomously. A quick burst of infrared light then triggered it to release its cargo. This October 3rd robotics update also covers advances in highlighting such a robots which can do cargo in the safest way.

Such adaptability could revolutionize disaster rescue missions, environmental monitoring, and underwater infrastructure inspections. Imagine swarms of these bots scouting flood zones, carrying medical supplies, or tracking pollution in wetlands.

6.Samsung’s Welding Robots Take Their First Steps in Shipyards

Shipbuilding is one of the toughest, most labor-intensive industries. Now, Samsung Heavy Industries is testing a new ally , a walking quadrupedal robot designed for welding, painting, and inspections.

Developed by Diden Robotics, the robot called Diden 30 has magnetic feet that let it walk on steel walls and ceilings, navigating environments too dangerous for human workers.

From KAIST Lab to Industrial Giant

Diden Robotics is a spinoff from KAIST’s Hu-bo Lab, known for advanced humanoid robots. The Diden 30 represents the lab’s first major step into heavy industry automation.

In September, the robot successfully completed welding tests on large ship blocks at Samsung’s shipyard a major milestone proving that robotic welders can handle real-world conditions.

Solving Labor Shortages at Sea

South Korea’s shipbuilding industry faces a severe labor shortage. With fewer skilled welders available, automation could keep production afloat. Diden’s robots are being customized not just for Samsung, but also for HD Hyundai, Hanwha Ocean, and HD Korea Shipbuilding.

The startup is also developing Diden Walker, a bipedal robot set for release in late 2025, designed to handle tight, confined shipyard spaces.

Why It Matters

Shipyards are some of the most hazardous industrial sites in the world. Robots like Diden 30 could reduce accidents, speed up construction, and fill critical labor gaps, while setting the stage for more advanced robotic workers in heavy industries.

7.From Screens to Robots: Apple Supplier BOE Expands Into AI and Automation

For decades, BOE Technology Group has been best known as the world’s largest display manufacturer, supplying screens to giants like Apple and Huawei. Now, the Beijing-based company is making a bold pivot into a very different arena robotics and artificial intelligence.

In September, BOE announced the launch of Beijing BOE Robot, a new subsidiary backed by 200 million yuan (US$28 million) in capital. Its mission? To design industrial robots and AI-driven automation systems that can help factories become smarter and more efficient.

Riding China’s Robotics Boom

The move is no coincidence. China now accounts for 54% of global industrial robot deployments, with nearly 300,000 new robots installed in 2024 alone more than the rest of the world combined. Domestic manufacturers are rapidly catching up with, and in some cases surpassing, foreign suppliers.

A recent Morgan Stanley report projected China’s robotics market will more than double to US$108 billion by 2028, driven by surging demand in manufacturing and logistics. BOE sees this as its chance to diversify beyond displays and secure a foothold in a sector growing at 23% annually.

A Strategic Shift for BOE

Founded in 1993, BOE employs nearly 100,000 people and has built a reputation for powering devices from iPhones to Huawei’s flagship smartphones. But the display market is intensely competitive, with shrinking profit margins. Robotics offers higher growth potential and aligns with China’s national strategy to automate its factories.

BOE now joins other tech giants like Foxconn and Ant Group, which are also pushing into robotics and embodied AI. The question is whether BOE’s deep supply chain expertise can translate into success in a whole new industry in other AI and robotics news, researchers have unveiled design industrial robots and AI-driven automation systems that can help factories become smarter and more efficient.

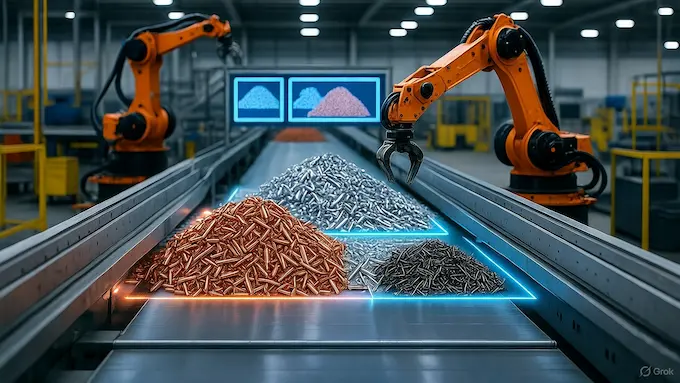

8. Sorting Steel With AI: ZenRobotics and USConveyor Revolutionize Scrap Recycling

In the world of steel recycling, purity is everything. Even a tiny amount of copper can ruin an entire batch of recycled steel, costing companies millions. That’s why one of America’s largest steel recyclers has turned to a pair of robotic innovators ZenRobotics and USConveyor.

This month, the two companies secured a repeat order for seven additional ZenRobotics Heavy Pickers, after successfully deploying three units in 2024. These AI-powered robots are transforming how scrap yards separate valuable metals from waste.

How the Heavy Picker Works

Unlike human workers who sort scrap by hand a dangerous, exhausting job ZenRobotics’ machines use computer vision and AI to identify copper, aluminum, steel, and waste materials at lightning speed. Mounted over conveyor belts, the robotic arms pluck out unwanted pieces with precision, running 24/7 without fatigue.

USConveyor’s role is critical: its engineers design systems that integrate the robots seamlessly into new and legacy scrap lines, even in tight or outdated facilities.

Why It Matters for the Steel Industry

Steel producers face increasingly strict purity standards — such as keeping copper content below 0.1%. With pressure rising for sustainability and circular economy practices, robotic sorting isn’t just about efficiency; it’s about survival.

As Troy Graves, President of USConveyor, put it: “The affordability and adaptability of the Heavy Picker make it a viable option for facilities of all sizes.”

This latest order signals a robotics revolution in recycling, where AI ensures safer workplaces, cleaner steel, and a greener future.

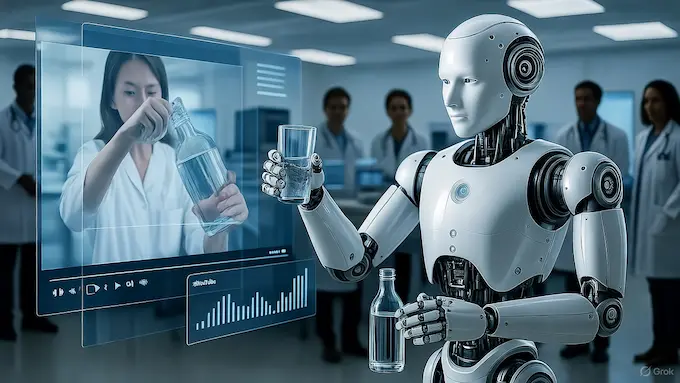

9.Teaching Robots With YouTube: INSAIT’s MotoVLA Redefines Robot Learning

One of the biggest bottlenecks in robotics is data. To learn new skills, robots typically require massive labeled datasets, painstakingly annotated by humans. But what if robots could learn simply by watching videos, the way humans learn by observation?

That’s exactly what researchers at INSAIT (Institute for Computer Science, Artificial Intelligence and Technology) in Sofia, Bulgaria, have achieved with their new system called MotoVLA.

Unveiled at the Conference on Robot Learning 2025 in Seoul, MotoVLA allows robots to acquire manipulation skills from unlabeled human and robot videos cutting out the need for thousands of manually labeled clips.

How MotoVLA Works

The system predicts 3D dynamics directly from video footage and aligns them with actions using only a small set of labeled data. This lets robots generalize far beyond what they’ve explicitly been taught, even performing entirely new tasks they’ve never seen before.

For example, instead of training a robot with thousands of “how to pour water” videos, MotoVLA could learn from generic human action clips, then infer the necessary motions to pour, stir, or carry objects.

A Leap in Generalization

This approach represents a major step toward general-purpose robots machines capable of improvising in real-world environments without exhaustive training.

INSAIT’s team, led by researchers Alexander Spiridonov, Dr. Jan-Nico Zaech, Nikolay Nikolov, Prof. Luc Van Gool, and Dr. Danda Paudel, believes MotoVLA could drastically reduce the cost and time of developing robotic skills.

In short, this is a breakthrough that could one day allow robots to learn from YouTube as easily as humans do.

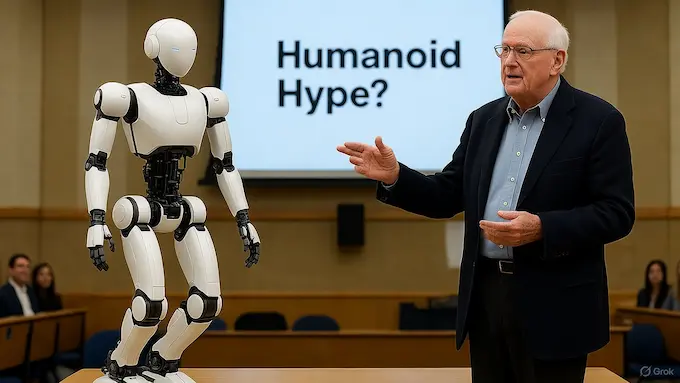

10.The $39B Fantasy? iRobot’s Co-Founder Calls Out the Humanoid Hype

The race to build human-like robots has attracted billions in investment, with companies like Tesla and Figure promising machines that will walk, work, and live alongside us. But not everyone is convinced. Rodney Brooks, co-founder of iRobot and the creator of the Roomba, has delivered a sharp warning: the humanoid robotics boom is “pure fantasy thinking.”

The Hand Problem Nobody Talks About

Brooks points to a critical flaw in the hype: human dexterity. The human hand has around 17,000 touch receptors that send continuous data to the brain. Robots today don’t come close to that level of sensitivity, yet startups keep promising humanoids that will learn complex tasks just by watching YouTube videos.

Without tactile feedback, Brooks argues, humanoids will never achieve the fine motor control needed for real-world usefulness.

The Physics of Falling Giants

There’s also the danger factor. Unlike wheeled robots, humanoids need constant energy to balance. A two-meter-tall robot tipping over doesn’t just stumble it falls with force equal to dropping a bowling ball from head height. That’s a major safety hazard in homes or workplaces.

Why Purpose-Built Wins

Brooks believes the future lies in task-specific robots: wheeled platforms with arms, advanced sensors, and clear roles. These already work in warehouses and factories, quietly transforming industries without the humanoid spectacle.

The warning echoes past bubbles like dot-com and crypto massive valuations built on shaky assumptions. With humanoid robotics valued at $39 billion despite no large-scale deployment, Brooks’ reality check couldn’t be more timely.

11.UK’s First Industrial Humanoid: A Giant on Wheels

In September, UK startup Humanoid unveiled the HMND 01 Alpha, the nation’s first humanoid robot designed specifically for industrial use. At 220 centimeters tall and capable of reaching 7.2 km/h on wheels, the robot is part futuristic giant, part factory assistant.

Built for Industry, Not Entertainment

Unlike flashy humanoids that dance or perform stunts, the HMND 01 Alpha has a practical mission: to support factories with repetitive, heavy, and hazardous tasks. It can carry payloads over 15 kilograms and is currently undergoing trials across industrial sites.

The insights gathered will shape the Beta version, slated for release in late 2026.

Big Backing, Big Ambitions

Humanoid is supported by $50 million in founder-led funding and boasts a team of alumni from Apple, Tesla, Google, Nvidia, and Boston Dynamics. Its business model is robots-as-a-service (RaaS) offering industrial clients robots on subscription rather than ownership.

With big names like Tesla, Nvidia, and Unitree driving humanoid development worldwide, the UK’s entry signals its ambition to carve a niche in this global race.

12.“Unitree CEO: From Dancing Robots to Practical Humanoid Assistants”

Three Stages to True Utility

Wang outlined a roadmap that could see humanoids transition from showpieces to genuine helpers:

- Programmed Actions – Predefined dances, martial arts, and tricks (achieved already).

- Real-Time Action Generation – Robots responding instantly to instructions, such as “pick up that box” (targeted by the end of 2025).

- General-Purpose Assistance – Robots handling open-ended requests like “I’m thirsty, bring me water,” even in unfamiliar environments (expected as early as 2026).

Overcoming Big Challenges

To reach stage three, Unitree must solve problems that plague the entire humanoid industry:

- Battery life for high-performance chips.

- Cooling systems to prevent overheating.

- Cable complexity, which often leads to breakdowns.

Why It Matters

If successful, Unitree’s humanoids could bridge the gap between entertainment and real-world utility. A humanoid that can operate in new environments, interpret human intent, and act independently would mark a turning point one that moves humanoid robots from novelty acts to everyday partners.

13.Meta vs. Tesla: The Humanoid Robot Showdown

For years, Mark Zuckerberg and Elon Musk have clashed over social media platforms, AI ethics, and even joked about a cage fight. Now, their rivalry is moving into new territory humanoid robots.

At stake is more than bragging rights it’s the future of AI-powered machines that could one day work in homes, factories, and offices.

Meta’s Vision: Robots Trained Through Human Eyes

Meta’s strategy starts with its latest AI glasses. Outwardly, they look like a wearable gadget. But built inside is a first-person data collection system. Each video captured cooking dinner, fixing a sink, setting a table can train AI models on how humans interact with the world.

Meta CTO Andrew Bosworth described the project as building a bridge between human experience and robotic intelligence. With millions of users, Meta could create a massive dataset of “how humans see and act,” teaching robots to mimic behavior in ways third-person videos never could.

Tesla’s Counter: Robots Learning From Cars

Tesla, meanwhile, is leaning on its self-driving car fleet. With over eight million vehicles on the road, Tesla has already amassed one of the world’s largest video datasets of real-world navigation. Musk argues the leap from cars to humanoids is natural both require real-time perception, decision-making, and movement in dynamic environments.

Tesla’s humanoid robot, Optimus, is already in testing. According to former Tesla VP Milan Kovac, the company recently achieved breakthroughs in transferring human video training directly into robot motion.

A Billion-Dollar Rivalry

Meta has been hiring top robotics researchers, offering packages worth hundreds of millions, while Musk has predicted 10 billion humanoid robots on Earth by 2040.

Both companies are chasing not just a product but control of an emerging market that could redefine work, service, and daily life. Whether Meta’s first-person vision or Tesla’s autonomous driving expertise wins out, one thing is certain: the humanoid robot race has officially begun.

14.Albania Appoints the World’s First AI Minister

Politics may never be the same again. In a world first, Albania has appointed an AI-powered virtual minister named Della to its national cabinet.

Presented as a digital avatar dressed in traditional Albanian clothing, Della is not a human politician but an AI bot tasked with overseeing public procurement and ensuring transparency in government contra

“I Am Not Here to Replace People”

During her introduction, Della addressed citizens directly:

“I am not here to replace people, but to assist them. I have no personal ambition or interests. I only have data, algorithms, and a dedication to serving citizens impartially.”

While Della doesn’t hold official voting power (only citizens over 18 can be ministers under Albanian law), the appointment is symbolic of a broader shift using AI as a tool for governance, anti-corruption, and efficiency.

A Global Experiment in AI Politics

Albania is not alone in exploring AI leadership:

- In Japan, a fringe party has proposed a chatbot penguin leader.

- In Ukraine, an AI spokesperson named Victoria already delivers official foreign ministry statements.

- In the U.S., a mayoral candidate once even ran with an AI chatbot as his campaign persona.

Risks and Questions

Supporters argue AI leaders could bring objectivity, tireless service, and corruption-free governance. Critics warn of risks:

- Whose values are embedded in the AI’s algorithms?

- Can citizens trust decisions made by a machine?

- What happens if AI “leaders” disagree with their human governments?

Why It Matters

Love it or fear it, Albania’s experiment signals the arrival of AI in the corridors of power. What began as automation in factories and homes is now edging into government raising the question if AI can run supply chains and surgeries, could it one day run a country? reviewing the top robotics stories of October, it’s clear that AI is advancing in politics and wishing work as a tool for governance, anti-corruption, and efficiency.

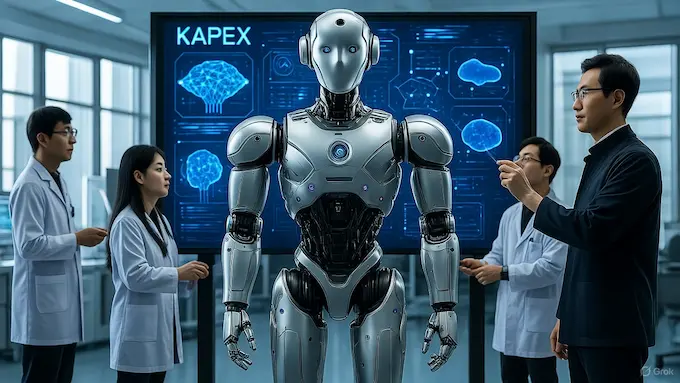

15. KAPEX: Korea’s Answer to the Humanoid Robot Race

This November, South Korea will officially enter the global humanoid race. The Korea Institute of Science and Technology (KIST) announced that it has co-developed a next-generation humanoid robot called KAPEX, in partnership with LG Electronics and LG AI Research.

At its core, KAPEX is powered by LG’s EXAONE Vision Language Model (VLM) an advanced “robot brain” that allows it to see, understand, and act in ways far beyond traditional humanoids.

More Than Just Movement

Unlike earlier humanoids built mainly to mimic human gestures, KAPEX is designed to learn, adapt, and collaborate. Its standout features include:

- Human-level physical strength with high-output actuators.

- A multi-finger robotic hand with tactile sensors nearly as sensitive as human skin.

- Reinforcement learning combined with VLM-powered adaptive intelligence.

- Advanced environmental perception and autonomous walking in complex spaces.

This makes KAPEX not just a moving robot, but an “intelligent companion” capable of performing household and industrial tasks at a human-equivalent level.

A Korean Alternative to U.S. and China

The humanoid platform is considered essential for Physical AI robots that can learn directly from the real world by moving, handling tools, and interacting with humans. Until now, the field has been dominated by the United States and China.

KAPEX challenges that balance, offering a uniquely Korean solution that emphasizes self-sufficiency and independence. By developing key actuators and core components domestically, the project strengthens Korea’s foothold in global robotics.

Toward a New Global Standard

According to Lee Jong-won, director general of KIST’s Humanoid Research Division:

“KAPEX will serve as a practical alternative and a new global standard as a Korean AI robot that challenges the U.S.-China-centered market order.”

The plan is ambitious: large-scale technology transfer, rapid commercialization, and field demonstrations within four years. If successful, KAPEX could become Korea’s flagship entry in the global humanoid race, reshaping the competitive landscape.

Why It Matters

Humanoids are no longer science fiction. They represent a critical platform for industries from manufacturing and logistics to healthcare and households. With KAPEX, Korea is signaling that it doesn’t just want to participate in the robotics revolution it wants to lead it Lets summarize the latest in robotics, the advancements from our weekly edition ROBOTICS NEWS October 03 ,2025:THE BOLT AND THE BYTE will bring authentic news to you be with us to get exiting and innovative short news on burning topics of robotics news & AI.

Q1. What are the most important robotics innovations this week?

ROMATRIS, the disaster-response robot, and Charlotte, the spider-bot that can 3D-print homes, are among the biggest highlights.

Q2. Are humanoid robots close to mass adoption?

Not yet. While Tesla, Meta, Unitree, and UK’s Humanoid are making progress, experts like iRobot’s Rodney Brooks warn that humanoids remain years away from widespread use.

Q3. Which countries are leading in robotics?

China leads industrial robot deployment, while Germany, South Korea, the U.S., and Australia are at the forefront of research and innovation.

Q4. Can AI really serve in government roles?

Albania made history by appointing an AI-powered virtual minister, showing how AI could assist with transparency and governance tasks.

Q5. What industries will robotics impact the most in 2025?

Key sectors include logistics, construction, shipbuilding, recycling, manufacturing, and even politics, as automation extends beyond factories.

Q6. What is KAPEX?

KAPEX is a next-generation humanoid robot developed by KIST, LG Electronics, and LG AI Research, featuring LG’s EXAONE Vision Language AI model.

Q7. Why is KAPEX important for Korea?

It marks Korea’s independent entry into the humanoid robotics race, challenging U.S. and China dominance while boosting domestic self-sufficiency.

Q8. Which industries could KAPEX impact?

KAPEX is designed for both household assistance and industrial tasks, with applications in logistics, manufacturing, and healthcare.

Impressive article 👏